Ball and Butterfly Valve Manufacturing: A Comprehensive Overview

Valves are indispensable components in the industrial world, controlling the flow of liquids, gases, and slurries within pipelines. Among the various types of valves, ball and butterfly valves are particularly popular due to their efficiency, durability, and versatility. This article explores the manufacturing processes, applications, market trends, and the future outlook for ball and butterfly valve manufacturing.

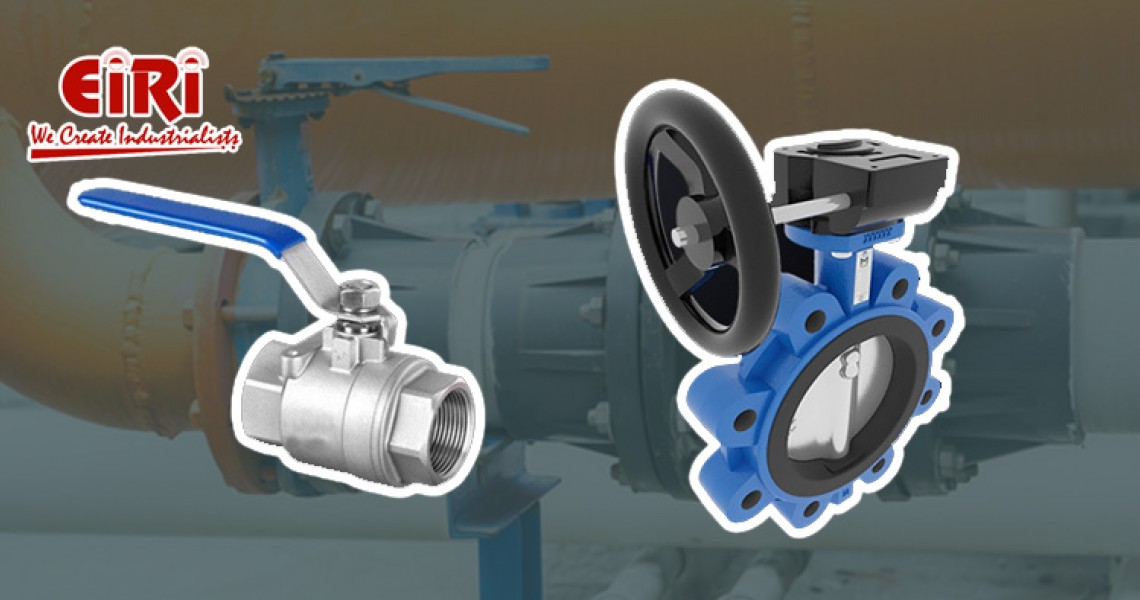

Ball Valves are quarter-turn valves that use a hollow, perforated, and pivoting ball to control flow. They are known for their tight sealing capabilities, making them suitable for applications requiring leak-proof service. Ball valves are used extensively in industries like oil and gas, water treatment, chemical processing, and more, due to their ability to provide reliable shutoff.

Butterfly Valves are also quarter-turn valves but use a rotating disk to regulate the flow. They are characterized by their compact size, lightweight construction, and quick operation. Butterfly valves are widely used in water distribution, wastewater treatment, and the food and beverage industry because of their ability to handle large volumes of fluids with minimal pressure drop.

Manufacturing Processes

The manufacturing of ball and butterfly valves involves several intricate steps, each requiring precision and adherence to stringent quality standards. Here's a detailed look at the processes involved:

1. Material Selection and Preparation

Both ball and butterfly valves are made from various materials including stainless steel, carbon steel, brass, and plastic. The choice of material depends on the intended application, considering factors like pressure, temperature, and the type of fluid being controlled. High-quality raw materials are crucial for ensuring the durability and performance of the valves.

2. Forging and Casting

The body and key components of the valves are typically produced through forging or casting processes. Forging involves shaping the metal under high pressure, enhancing its strength and durability. Casting, on the other hand, involves pouring molten metal into molds to form the desired shapes. Both processes require precise control to ensure the integrity and dimensional accuracy of the components.

3. Machining

After forging or casting, the components undergo machining processes to achieve the required dimensions and surface finishes. This includes turning, milling, drilling, and grinding. Computer Numerical Control (CNC) machines are often used to ensure high precision and consistency in the production of valve parts.

4. Assembly

The machined components are then assembled. For ball valves, this involves inserting the ball into the valve body, attaching the stem, and fitting the seats and seals. Butterfly valve assembly includes mounting the disk onto the stem and securing it within the valve body. During assembly, special attention is paid to aligning the components correctly to ensure smooth operation.

5. Testing and Quality Control

Quality control is paramount in valve manufacturing. Each valve undergoes rigorous testing to verify its performance under various conditions. This includes pressure testing, leak testing, and operational testing to ensure the valves function correctly and meet industry standards. Non-destructive testing methods, such as ultrasonic and radiographic testing, are also used to detect any internal defects.

6. Surface Treatment and Coating

To enhance durability and resistance to corrosion, valves often undergo surface treatments and coatings. This can include electroplating, powder coating, or applying special anti-corrosive paints. The choice of coating depends on the environmental conditions the valve will be exposed to.

Applications of Ball and Butterfly Valves

Ball and butterfly valves are integral to numerous industries due to their reliability and efficiency in controlling fluid flow. Here are some key applications:

1. Oil and Gas Industry

In the oil and gas sector, ball valves are essential for isolating and controlling the flow of hydrocarbons. Their ability to provide tight shutoff and handle high pressures makes them ideal for upstream, midstream, and downstream applications. Butterfly valves are also used in this industry for regulating the flow in large pipelines and managing the flow of gases and slurries.

2. Water Treatment and Distribution

Both ball and butterfly valves are extensively used in water treatment plants and distribution systems. Ball valves ensure reliable shutoff in critical applications, while butterfly valves are favored for their compact size and ability to control large flow volumes efficiently. They are used in various stages of water treatment, from raw water intake to distribution of treated water.

3. Chemical Processing

In chemical plants, the handling of aggressive and corrosive fluids requires valves that can withstand harsh conditions. Stainless steel ball and butterfly valves are commonly used due to their resistance to corrosion and chemical attack. They are vital in controlling the flow of chemicals, ensuring safety, and maintaining process integrity.

4. Food and Beverage Industry

Hygiene and safety are paramount in the food and beverage industry. Ball and butterfly valves made from food-grade materials are used to control the flow of liquids and gases in production processes. Their easy-to-clean design and resistance to contamination make them suitable for applications involving dairy products, beverages, and other consumables.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, ball and butterfly valves regulate the flow of water and air. They are used in chiller systems, cooling towers, and air handling units to ensure efficient operation and maintain optimal indoor environmental conditions.

Market Trends and Opportunities

The global market for ball and butterfly valves is experiencing significant growth, driven by increasing demand from various industries and advancements in valve technology. Key trends and opportunities in the market include:

1. Automation and Smart Valves

The integration of automation and smart technologies in valve systems is a growing trend. Automated ball and butterfly valves equipped with sensors and actuators enable remote monitoring and control, enhancing operational efficiency and reducing downtime. Smart valves also facilitate predictive maintenance, minimizing the risk of unexpected failures.

2. Environmental Regulations

Stringent environmental regulations and the push for sustainability are driving the demand for eco-friendly valve solutions. Manufacturers are focusing on developing valves that reduce emissions, minimize energy consumption, and support the use of renewable energy sources.

3. Expansion in Emerging Markets

The rapid industrialization and urbanization in emerging markets, particularly in Asia-Pacific, present significant growth opportunities for valve manufacturers. The increasing demand for infrastructure development, water treatment facilities, and energy production is boosting the need for reliable valve solutions.

4. Customization and Specialized Valves

Industries with specific requirements are seeking customized and specialized valve solutions. Manufacturers are investing in research and development to design valves that meet the unique needs of different applications, such as high-pressure systems, corrosive environments, and sanitary processes.

Conclusion

The manufacturing of ball and butterfly valves is a complex process that demands precision, quality control, and adherence to industry standards. These valves play a crucial role in various industries, from oil and gas to water treatment, chemical processing, and food and beverage production. As market demand continues to grow, driven by industrial expansion and technological advancements, the valve manufacturing sector presents significant opportunities for innovation and growth.

Future trends in automation, environmental sustainability, and market expansion highlight the evolving landscape of the valve industry. By embracing these trends and focusing on customization and quality, valve manufacturers can continue to meet the diverse needs of their customers and contribute to the efficiency and safety of industrial processes worldwide.