Carbon Nanotube Manufacturing Business Explained

Carbon nanotubes (CNTs) represent a groundbreaking advancement in materials science, offering remarkable properties that have sparked widespread interest across industries. As a result, the carbon nanotube manufacturing business has emerged as a dynamic and promising sector with immense potential. This article delves into the intricacies of carbon nanotube production, exploring the methods, applications, market trends, and future prospects of this burgeoning industry.

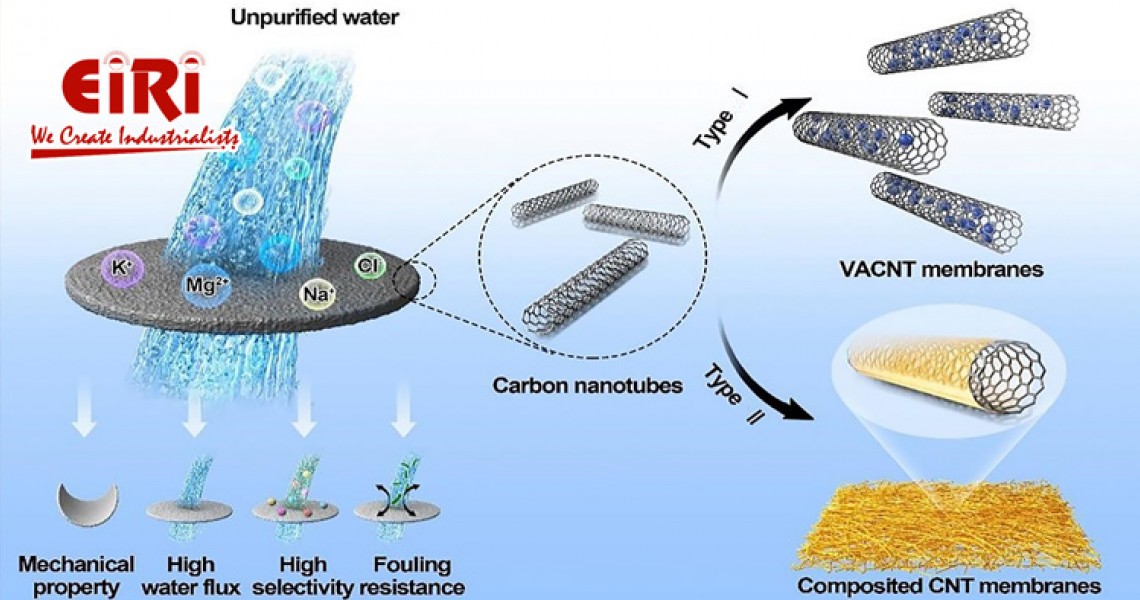

Carbon nanotubes (CNTs) are cylindrical nanostructures made of carbon atoms arranged in a hexagonal lattice. They have exceptional mechanical, electrical, and thermal properties, making them one of the most promising materials for various applications.

Understanding Carbon Nanotubes:

Carbon nanotubes are cylindrical nanostructures composed of carbon atoms arranged in a hexagonal lattice pattern. They can be single-walled (SWCNTs), consisting of a single layer of carbon atoms, or multi-walled (MWCNTs), comprising multiple concentric layers. CNTs exhibit extraordinary mechanical strength, exceptional electrical conductivity, and superior thermal properties, making them highly versatile materials with applications spanning from electronics and aerospace to medicine and energy storage.

Methods of Carbon Nanotube Manufacturing:

Several methods are employed for the production of carbon nanotubes, each offering unique advantages and challenges. The most common techniques include arc discharge, laser ablation, chemical vapor deposition (CVD), and catalytic chemical vapor deposition (CCVD). CVD and CCVD methods are widely used for large-scale production due to their scalability and ability to control the properties of the synthesized nanotubes. These techniques involve the decomposition of hydrocarbon gases in the presence of a catalyst at elevated temperatures to grow carbon nanotubes on substrates. Let's delve into the technical aspects of each method of carbon nanotube (CNT) manufacturing:

Arc Discharge:

Arc discharge is one of the earliest methods developed for producing carbon nanotubes. In this technique, a high electrical current is passed between two graphite electrodes in an inert gas atmosphere, typically helium. The intense heat generated by the arc vaporizes the graphite electrodes, leading to the formation of a carbon plasma. Carbon atoms from the plasma then condense to form carbon nanotubes on the cooler surfaces of the reactor chamber. Arc discharge is known for its simplicity and relatively low cost, but it produces a mixture of carbon structures, including nanotubes, nanofibers, and amorphous carbon, making purification challenging.

Laser Ablation:

Laser ablation involves the use of a high-power laser to vaporize a graphite target in a high-temperature furnace filled with an inert gas, such as argon or helium. The laser beam heats the graphite target to extreme temperatures, causing it to evaporate and form a plasma plume. Carbon atoms within the plasma rapidly cool and condense to form carbon nanotubes on a substrate placed downstream from the graphite target. Laser ablation offers precise control over the synthesis parameters and enables the production of high-purity carbon nanotubes with defined structural properties. However, it is limited by its low production yield and scalability challenges.

Chemical Vapor Deposition (CVD):

Chemical vapor deposition (CVD) is a widely used method for the large-scale synthesis of carbon nanotubes with controlled properties. In CVD, hydrocarbon gases, such as methane or ethylene, are introduced into a high-temperature furnace along with a catalyst, typically transition metal nanoparticles like iron, cobalt, or nickel supported on a substrate, such as silicon or quartz. The hydrocarbon gases decompose in the presence of the catalyst at elevated temperatures, forming carbon radicals. These radicals then recombine and grow into carbon nanotubes on the catalyst surface. CVD offers excellent scalability, controllability, and the ability to produce high-quality carbon nanotubes with tailored properties.

Catalytic Chemical Vapor Deposition (CCVD):

Catalytic chemical vapor deposition (CCVD), also known as floating catalyst CVD, is a variation of the CVD method that involves the introduction of catalyst nanoparticles into the reaction chamber as a fine powder or aerosol. The catalyst nanoparticles act as nucleation sites for carbon nanotube growth, facilitating the formation of vertically aligned nanotube arrays. CCVD offers advantages such as enhanced catalyst utilization efficiency, improved control over nanotube diameter and alignment, and compatibility with continuous production processes. It is widely used for synthesizing vertically aligned carbon nanotube forests for applications such as field emission devices and nanocomposites.

Overall, these methods offer unique advantages and challenges in carbon nanotube manufacturing, with chemical vapor deposition techniques standing out for their scalability, controllability, and versatility in producing high-quality nanotubes for diverse applications.

Applications Across Industries:

The exceptional properties of carbon nanotubes have led to their integration into a diverse range of applications across various industries. In the electronics sector, CNTs are utilized in the development of high-performance transistors, flexible displays, and conductive films. In aerospace and automotive industries, they enhance the mechanical strength and reduce the weight of structural components, leading to improved fuel efficiency and performance. Moreover, carbon nanotubes find applications in healthcare for drug delivery, biosensing, and tissue engineering, thanks to their biocompatibility and unique physicochemical properties.

Let's explore the applications of carbon nanotubes (CNTs) across different industries:

Electronics:

Carbon nanotubes are extensively used in the electronics industry due to their remarkable electrical properties. They serve as building blocks for high-performance transistors, enabling the development of faster and more efficient electronic devices. Additionally, CNTs are incorporated into flexible displays and touchscreens, offering enhanced durability and flexibility compared to traditional materials. Conductive films made from carbon nanotubes are utilized in applications such as transparent electrodes, electromagnetic shielding, and anti-static coatings.

Aerospace and Automotive:

In the aerospace and automotive industries, carbon nanotubes are valued for their exceptional mechanical properties, including high strength, stiffness, and low density. They are used to reinforce composite materials, such as carbon fiber composites, to improve structural integrity and reduce weight. By incorporating carbon nanotubes into components like aircraft wings, automotive bodies, and engine parts, manufacturers can achieve significant improvements in fuel efficiency, performance, and durability. Moreover, CNT-based materials exhibit excellent thermal and electrical conductivity, making them suitable for heat management and electromagnetic interference shielding in aerospace and automotive applications.

Healthcare and Biomedical:

Carbon nanotubes hold great promise in healthcare and biomedical applications owing to their biocompatibility and unique physicochemical properties. They are used in drug delivery systems to encapsulate and transport therapeutic agents to targeted sites within the body, offering precise control over drug release kinetics. CNT-based biosensors are employed for detecting biomolecules and pathogens with high sensitivity and specificity, making them valuable tools for medical diagnostics and disease monitoring. Furthermore, carbon nanotubes serve as scaffolds in tissue engineering, providing a supportive framework for cell growth and tissue regeneration in applications such as bone implants, wound dressings, and neural interfaces.

Carbon nanotubes play a pivotal role in revolutionizing various industries by enabling the development of advanced electronic devices, lightweight structural materials, and innovative biomedical technologies. Their unique combination of mechanical, electrical, and biological properties continues to inspire new applications and drive technological advancements across diverse sectors.

Market Trends and Growth Drivers:

The carbon nanotube manufacturing market is witnessing robust growth, driven by increasing demand from sectors such as electronics, aerospace, and healthcare. Advancements in production techniques, coupled with growing investments in research and development, are expanding the commercial viability of CNTs. Additionally, the rising focus on sustainability and environmental conservation is driving the adoption of carbon nanotubes in energy storage, catalysis, and environmental remediation applications.

Growth Factors

Carbon nanotubes boast remarkable electrical, physical, and thermal properties, making them indispensable in various sectors. With dimensions spanning mere nanometers, these structures exhibit exceptional electrical conductivity and tensile strength while enduring extreme temperatures. In the polymers industry, carbon nanotubes serve as reinforcing agents, enhancing strength and reducing weight. Turbine blades benefit from their mechanical robustness, extending the lifespan of wind turbines. Moreover, carbon nanotubes feature prominently in electronic displays for devices like TVs, laptops, and phones, catering to the surging demand for consumer electronics worldwide, especially in the burgeoning markets of the Asia Pacific region.

The electronics sector is a prime beneficiary of carbon nanotubes' superior mechanical and electronic characteristics. With technological advancements and robust development in regions like Japan, South Korea, and China, demand for electronic goods is soaring. Consequently, manufacturers are increasingly incorporating carbon nanotubes to meet the escalating demand. The semiconductor industry, in particular, is witnessing a surge in demand, further driving the adoption of carbon nanotubes. With ongoing technological breakthroughs and substantial investments from key players, the carbon nanotubes market is poised for exponential growth in the foreseeable future.

Carbon nanotubes are revolutionizing medical applications, particularly in the realm of diagnostics and treatment. Their utilization in X-rays and tumor detection underscores their versatility and potential in advancing healthcare. As research continues and new avenues emerge, carbon nanotubes are poised to play an increasingly pivotal role in shaping various industries and driving innovation across sectors.

Furthermore, supportive government initiatives and collaborations between academia and industry are fostering innovation and driving market growth.

Future Outlook and Opportunities:

The carbon nanotubes market was valued at $2 billion in 2022, projected to reach $7.71 billion by 2032, with a CAGR of 14.50% during 2023-2032.

Looking ahead, the carbon nanotube manufacturing business is poised for continued expansion and innovation. Emerging technologies such as roll-to-roll production methods and post-synthesis functionalization techniques hold promise for enhancing the scalability, functionality, and cost-effectiveness of carbon nanotubes. Moreover, the development of hybrid nanomaterials and composites incorporating CNTs is expected to unlock new applications and markets. As research continues to unravel the full potential of carbon nanotubes, the industry is primed to play a pivotal role in shaping the future of materials science and technology.

Conclusion:

The carbon nanotube manufacturing business represents a dynamic and rapidly evolving sector with vast opportunities for growth and innovation. With their exceptional properties and diverse applications, carbon nanotubes have emerged as a game-changing material poised to revolutionize numerous industries. By leveraging advanced production techniques, exploring novel applications, and fostering collaborations, stakeholders in the carbon nanotube industry can unlock the full potential of this remarkable nanomaterial and drive progress towards a more sustainable and technologically advanced future.