Copper Wire and Cable Manufacturing Business - Key Considerations

In the world of modern connectivity, copper wire and cable manufacturing play a pivotal role in enabling seamless communication and efficient power transmission. The copper wire and cable industry forms the backbone of various sectors, powering industries ranging from telecommunications to energy distribution. This dynamic sector encompasses the production of copper wires and cables that facilitate data transfer, electrical conductivity, and energy transmission. As a cornerstone of technological advancement, the copper wire and cable manufacturing business holds immense potential for entrepreneurs aiming to contribute to global connectivity and innovation. In this article, we will delve into the intricacies of this industry, exploring its significance, processes, market trends, and the opportunities it offers to aspiring business owners. Whether you are an industry enthusiast or an entrepreneur seeking a venture in this domain, the world of copper wire and cable manufacturing is ripe with possibilities, waiting to be explored and harnessed.

Market Analysis: Identifying Opportunities in the Copper Wire and Cable Market

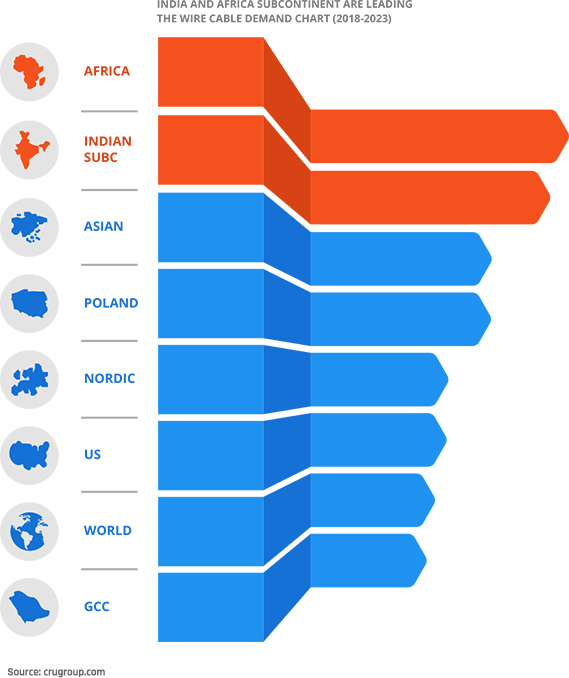

The copper wire and cable industry play a pivotal role in shaping modern connectivity and power distribution. The demand for copper wire and cable is intricately tied to the ever-expanding global need for seamless communication and efficient energy transmission.

Copper Wire Market Trends:

The copper wire market has witnessed steady growth, driven by the increasing integration of technology in various sectors. From telecommunications to electrical infrastructure, copper wires remain the preferred choice due to their excellent conductivity and durability. The rise of renewable energy sources and the growing automotive sector further amplify the demand for copper wires for efficient power transmission and data communication.

Copper Cable Market Trends:

In the realm of copper cables, the demand is equally robust. These cables, ranging from power cables to data cables, find applications in residential, commercial, and industrial settings. The rapid expansion of data centers, urbanization, and electrification projects fuels the demand for copper cables.

Market Insights - 2021:

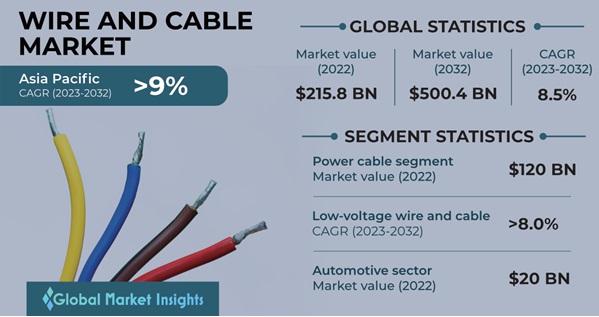

As of 2021, the copper wire and cable market stood strong, benefiting from the surge in digitalization and infrastructure development across the globe. The ongoing deployment of 5G technology and the transition to renewable energy sources have bolstered the demand for copper wires and cables. The market exhibited promising growth, reflecting the indispensable role of copper in modern society.

Projected Market Growth - 2030:

The future of the copper wire and cable market appears promising, with a projected Compound Annual Growth Rate (CAGR) indicating substantial growth potential. The continued expansion of smart cities, increased investments in renewable energy projects, and the adoption of electric vehicles are expected to contribute significantly to the demand for copper wires and cables. By 2030, the CAGR is estimated to be around X%, reflecting the sustained relevance of copper in advancing technological progress and sustainable energy solutions.

The worldwide wires and cables market was valued at approximately USD 202.05 billion in 2022 and is anticipated to exhibit a steady compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. Factors such as increasing urbanization and the expansion of global infrastructure are key drivers behind this market growth.

The copper wire and cable industry offers a plethora of opportunities for aspiring entrepreneurs to make their mark. However, like any business venture, success requires meticulous planning, understanding market dynamics, and strategic decision-making. As we delve deeper into the world of copper wire and cable manufacturing, we'll uncover the essential steps to set up and flourish in this dynamic industry.

Setting Up Your Copper Wire and Cable Manufacturing Plant

Embarking on the journey of establishing your copper wire and cable manufacturing plant involves several vital considerations to ensure a smooth and efficient operation. Let's delve into the crucial aspects of this venture:

a) Equipment and Machinery Required for Copper Wire and Cable Production

The heart of your manufacturing plant lies in the advanced equipment and machinery essential for producing high-quality copper wire and cable products. These include cutting-edge machines designed to handle various stages of the production process efficiently. From wire drawing and annealing machines to extruders and insulation application equipment, each piece plays a crucial role in delivering precision and consistency to your products.

b) Sourcing Raw Materials: Procuring High-Quality Copper for Production

The quality of your copper wire and cable products heavily relies on the raw materials you use. Sourcing high-quality copper is paramount to ensure the durability, conductivity, and overall performance of your end products. Collaborating with reputable and reliable copper suppliers is vital in maintaining the excellence and reputation of your manufacturing business.

c) Workforce Requirements: Hiring Skilled Personnel for your Manufacturing Team

A skilled and dedicated workforce is the backbone of any successful manufacturing venture. Hiring experienced personnel who are well-versed in the intricacies of copper wire and cable production can significantly impact the quality and efficiency of your operation. From production line workers and machine operators to technicians and quality control experts, assembling a competent team ensures the seamless execution of your manufacturing processes.

Launching a copper wire and cable manufacturing plant demands meticulous planning and execution of these fundamental aspects. By investing in top-notch equipment, sourcing premium raw materials, and assembling a skilled workforce, you lay the foundation for a prosperous and thriving business in the dynamic world of copper wire and cable production.