Ethyl Acetate : A Versatile Solvent with Global Significance

The ethyl acetate industry plays a pivotal role in various sectors of the global economy, providing a versatile solvent with a wide range of applications. This colorless liquid, characterized by its sweet, fruity odor, is known for its exceptional solvent properties, making it indispensable in industries such as paints and coatings, pharmaceuticals, food and beverages, adhesives, and cosmetics. In this article, we delve into the fascinating world of ethyl acetate, exploring its production, properties, and its diverse range of applications.

Production of Ethyl Acetate

Ethyl acetate is primarily synthesized through the esterification process, which involves the reaction of ethanol and acetic acid in the presence of a catalyst, commonly sulfuric acid. This chemical reaction results in the formation of ethyl acetate and water. Additionally, it can be produced through fermentation processes, where microorganisms transform ethanol and acetic acid into ethyl acetate.

It's important to note that while sulfuric acid is a common catalyst used in the production of ethyl acetate, other catalysts can also be employed based on specific manufacturing processes and desired product specifications. Additionally, some production methods involve the use of alternative feedstocks or bio-based sources of ethanol and acetic acid to align with sustainability and environmental goals.

Overall, the production of ethyl acetate relies on a well-controlled esterification reaction to efficiently convert ethanol and acetic acid into this valuable solvent with diverse industrial applications.

One of the standout features of ethyl acetate is its fast evaporation rate, a quality highly sought after in industries where quick drying is essential. This characteristic makes it an ideal solvent for paints, coatings, and adhesives, where rapid solvent evaporation is crucial for efficient application and drying processes. Furthermore, ethyl acetate boasts excellent solvency power, making it effective at dissolving a wide range of organic compounds, from resins and polymers to oils and fats.

What is the future of ethyl acetate?

The market for ethyl acetate in India had a total worth of $432.0 million in the year 2021. Looking ahead, it is anticipated to witness substantial growth, reaching an estimated value of $824.4 million by the year 2031. This expected growth reflects a steady Compound Annual Growth Rate (CAGR) of 6.7% from 2022 to 2031, signifying a promising trend in the industry's expansion.

On a global scale, the ethyl acetate market exhibited robust performance, with a market size of approximately USD 5,779.33 million in 2022. Projections for the future indicate further growth at an impressive Compound Annual Growth Rate (CAGR) of 8.5% throughout the forecast period. By the year 2028, the global ethyl acetate market is expected to soar to a substantial value of USD 9,427.03 million. These figures underscore the significant and consistent growth prospects within the global ethyl acetate industry, driven by various applications and market dynamics.

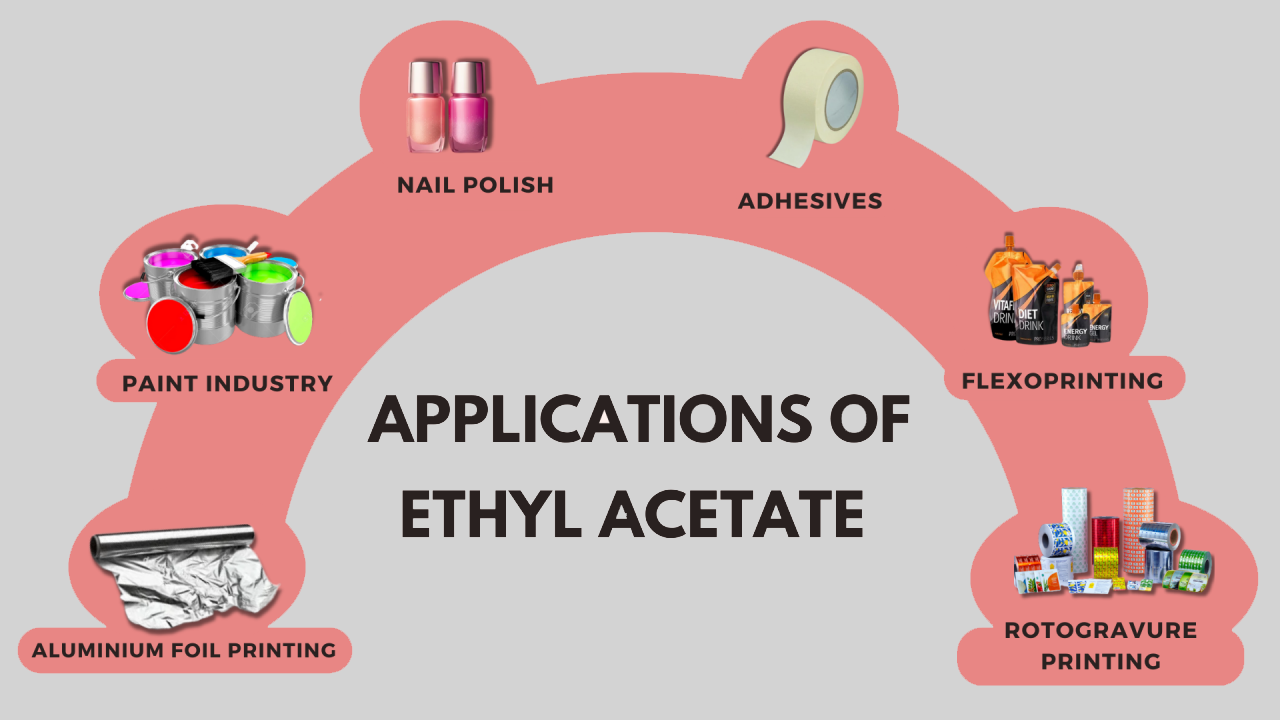

Applications of Ethyl Acetate

Ethyl acetate, characterized by its colorless nature, volatility, and fruity aroma, is a versatile chemical widely utilized in multiple industries across India. Its main applications span pharmaceuticals, paints and coatings, printing inks, adhesives, and even the food flavoring sector.

In the pharmaceutical domain, ethyl acetate plays a pivotal role as a solvent in the manufacturing processes of drugs, particularly in the extraction of active pharmaceutical ingredients (APIs) from plants. Given India's prominent position as a producer of generic drugs, the demand for ethyl acetate as a solvent remains on a constant upward trajectory, perfectly aligning with the growth of the Indian pharmaceutical sector.

Within the paints and coatings industry, ethyl acetate serves as an essential solvent, finding use in nitrocellulose lacquers, acrylic lacquers, and various coating systems. The flourishing construction industry in India has resulted in heightened demand for paints and coatings, consequently bolstering the need for ethyl acetate as a solvent. This aligns with the broader expansion of the construction sector.

Furthermore, India's printing industry also relies on ethyl acetate as a solvent for inks. Ethyl acetate-based inks possess desirable characteristics such as fast-drying properties and the ability to produce high-quality prints. This makes them exceptionally suitable for printing applications across diverse surfaces, including paper, plastic, and metal. The versatility of ethyl acetate in these applications underscores its significance in various industrial processes in India.

Paints and Coatings: One of the primary applications of ethyl acetate is in the formulation of paints and coatings. It serves as a key solvent that helps dissolve and disperse various components in paint formulations. Its fast evaporation rate allows for quick drying of paints, contributing to improved efficiency in the painting process. Ethyl acetate-based paints are known for their smooth finish and rapid drying time, making them popular in both industrial and residential settings.

Adhesives: In the adhesive industry, ethyl acetate is utilized as a solvent in the production of adhesives and glues. It aids in the formulation of adhesive solutions and helps achieve the desired viscosity and adhesive properties. The solvent's ability to evaporate rapidly ensures that bonded surfaces adhere quickly, making it suitable for various adhesive applications, from woodworking to packaging.

Pharmaceuticals: Ethyl acetate finds application in the pharmaceutical industry, particularly in the extraction and purification of pharmaceutical compounds. It is employed in processes such as liquid-liquid extraction and crystallization. Ethyl acetate's solvency power and low toxicity make it a preferred choice for these critical pharmaceutical processes.

Food and Beverages: Within the food industry, ethyl acetate plays a role in extracting flavors and fragrances from natural sources. It is used to capture the essence of fruits, spices, and other natural ingredients for flavoring various food and beverage products. Ethyl acetate is generally recognized as safe (GRAS) when used in accordance with food safety regulations.

Cosmetics and Fragrances: Ethyl acetate is a common ingredient in the cosmetics and fragrance industry. It is found in nail polish removers, perfumes, and fragrances. Its pleasant odor and effective solvent properties make it a valuable component in these products.

Chemical Synthesis: Ethyl acetate also has applications in chemical synthesis, where it serves as a versatile reagent and solvent. It is used in various laboratory and industrial processes for the synthesis of organic compounds.

The ethyl acetate industry plays an essential role in numerous sectors, offering a solvent that combines rapid evaporation with excellent solvency power. Its diverse range of applications, from paints and pharmaceuticals to food and cosmetics, highlights its versatility and importance in modern manufacturing and everyday life. As industries continue to innovate, ethyl acetate remains a valuable and indispensable component in their processes, contributing to efficiency, quality, and performance across various sectors.