Hemodialysis Blood Tube Manufacturing - Vascular Access Devices - Dialysis Tubing - Bloodline Sets

The healthcare industry continues to expand, driven by technological advancements and the increasing prevalence of chronic diseases. One such critical area is hemodialysis, a life-saving treatment for individuals with kidney failure. Hemodialysis blood tubing sets are vital components of this treatment, facilitating the filtration of blood and removal of waste products. Starting a hemodialysis blood tubing manufacturing business presents a unique opportunity to contribute to healthcare while tapping into a growing market demand.

Before delving into the specifics of starting a manufacturing business, it's essential to grasp the dynamics of the hemodialysis market. With the rising incidence of renal diseases worldwide, the demand for hemodialysis treatments is on the ascent. According to data from Market Research Future, the global hemodialysis market is projected to reach USD 103.88 billion by 2027, driven by factors such as the aging population, the prevalence of diabetes and hypertension, and technological advancements in dialysis equipment.

Hemodialysis Blood Tubing Overview

Hemodialysis blood tubing sets are essential components used in hemodialysis, a medical procedure that helps filter waste products and excess fluids from the blood when the kidneys are unable to perform this function adequately. The primary purpose of hemodialysis blood tubing sets is to facilitate the movement of blood from the patient to the dialysis machine and back.

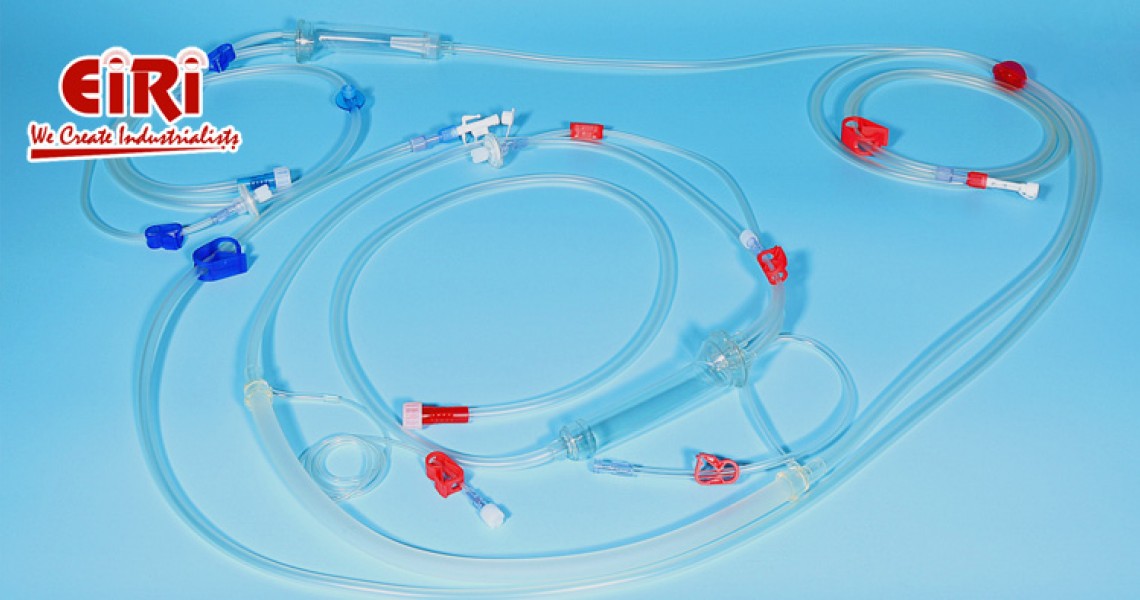

These sets typically consist of various components, including arterial and venous lines, a dialyzer connector, and other necessary tubing and connectors. During hemodialysis, the arterial line carries blood from the patient to the dialyzer, where it undergoes filtration to remove waste and excess fluid. The venous line then returns the filtered blood back to the patient's bloodstream.

Hemodialysis blood tubing sets are designed to ensure the safety and efficiency of the dialysis process. They are sterile and disposable to prevent the risk of infection and cross-contamination between patients. Additionally, these sets are engineered to maintain the proper flow rate and pressure needed for effective dialysis treatment while minimizing the risk of blood clotting or air embolisms.

Hemodialysis blood tubing sets are intricate devices comprising several components essential for the safe and efficient conduct of dialysis treatment. These components include arterial and venous lines, dialyzer connectors, tubing clamps, and specialized connectors for interfacing with dialysis machines. Each component must meet stringent quality standards to ensure patient safety and treatment efficacy.

The Hemodialysis Blood Tubing Sets Market is poised for significant growth, with revenue expected to surge at an impressive CAGR during the forecast period from 2023 to 2030. This growth is fueled by the escalating demand for Hemodialysis Blood Tubing Sets across a spectrum of applications, including Public Hospitals, Private Clinics, Nursing Homes, Personal Care, and others, on a global scale. The comprehensive report not only highlights lucrative opportunities within the Hemodialysis Blood Tubing Sets Market but also offers insights at the country level. It meticulously outlines costs, segments, trends, regional dynamics, and commercial advancements of key players worldwide for the projected period.

Diving deeper, the Hemodialysis Blood Tubing Sets Market report serves as a repository of data, analyzing market trends and dynamics within the industry. With a forecast period spanning from 2023 to 2030, the report amalgamates both quantitative and qualitative data, taking into account various factors such as product pricing, market penetration at regional and national levels, country GDP, and the prevailing economic, political, and social landscapes. By segmenting the market into various categories, the report provides a comprehensive analysis from every conceivable angle.

Steps for Starting Hemodialysis Blood Tubing Manufacturing

Market Analysis and Feasibility Study:

Conducting a comprehensive market analysis and feasibility study is crucial before venturing into hemodialysis blood tubing manufacturing. This entails researching market trends, identifying competitors, understanding regulatory requirements, and assessing manufacturing costs. It's essential to gauge the demand for hemodialysis blood tubing sets in different regions and segments of the market to tailor your business strategy accordingly.

Regulatory Compliance and Quality Standards:

Manufacturing medical devices such as hemodialysis blood tubing sets entails stringent regulatory compliance and adherence to quality standards. Depending on your target market, you may need to obtain certifications from regulatory authorities such as the FDA (Food and Drug Administration) in the United States or the CE (Conformité Européenne) marking in Europe. Ensuring compliance with ISO standards for medical devices is also paramount to guarantee product quality and safety.

Research and Development:

Investing in research and development (R&D) is essential for innovation and product differentiation in the competitive landscape of hemodialysis blood tubing manufacturing. Collaborating with healthcare professionals, engineers, and researchers can help identify opportunities for improvement and develop innovative solutions to enhance the performance and safety of blood tubing sets. R&D efforts should focus on materials engineering, design optimization, and compatibility with emerging dialysis technologies.

Supply Chain Management:

Establishing a robust supply chain is critical for the uninterrupted production of hemodialysis blood tubing sets. This involves sourcing high-quality raw materials, establishing relationships with reliable suppliers, and implementing efficient inventory management practices. Ensuring a steady supply of components and materials is essential to meet production schedules and maintain product quality standards.

Production Facilities and Equipment:

Setting up production facilities equipped with state-of-the-art equipment is essential for manufacturing hemodialysis blood tubing sets efficiently and cost-effectively. Depending on the scale of your operation, you may choose to manufacture in-house or outsource certain processes to contract manufacturers. Investing in automation and quality control systems can streamline production processes and ensure consistency in product quality.

Quality Control and Assurance:

Implementing robust quality control and assurance measures is paramount to ensure the safety and efficacy of hemodialysis blood tubing sets. This involves conducting thorough inspections and testing of raw materials, in-process components, and finished products to detect any defects or deviations from quality standards. Adhering to Good Manufacturing Practices (GMP) and implementing a quality management system (QMS) is essential for achieving regulatory compliance and building trust with customers.

Market Entry Strategy:

Developing a sound market entry strategy is crucial for successfully launching your hemodialysis blood tubing manufacturing business. This involves identifying target markets, establishing distribution channels, and developing marketing and sales strategies to promote your products. Collaborating with healthcare institutions, dialysis centers, and medical distributors can help penetrate the market and gain traction.

Conclusion:

Starting a hemodialysis blood tubing manufacturing business requires careful planning, meticulous execution, and a commitment to quality and innovation. By understanding market dynamics, investing in research and development, ensuring regulatory compliance, and building a robust supply chain, you can position your business for success in this growing industry. With the potential to make a significant impact on healthcare outcomes, hemodialysis blood tubing manufacturing presents a compelling opportunity for entrepreneurs seeking to combine business acumen with social impact.