Instant Coffee (Freeze-Dried) Manufacturing: A Comprehensive Guide

Instant coffee, especially freeze-dried coffee, has become a popular choice among consumers due to its convenience, long shelf life, and ability to retain the rich flavor and aroma of freshly brewed coffee. Freeze-drying, a method that preserves the quality of the coffee, involves removing water through sublimation, turning ice directly into vapor without passing through the liquid stage. This process ensures that the coffee maintains its natural flavors and essential oils. This detailed guide will explore the various aspects of manufacturing freeze-dried instant coffee, including market potential, production process, necessary equipment, financial considerations, and the challenges and opportunities in the industry.

Market Potential Instant Coffee Business

The global instant coffee market has witnessed significant growth in recent years, with freeze-dried coffee gaining popularity among consumers seeking premium quality instant coffee. The demand for instant coffee is driven by the fast-paced lifestyle of modern consumers, who seek convenience without compromising on taste and quality. According to market research, the instant coffee market is expected to continue growing, with freeze-dried coffee playing a crucial role due to its superior quality compared to traditional spray-dried coffee.

The rising popularity of coffee culture, increasing disposable income, and the growth of the urban population are key factors driving the demand for instant coffee. Moreover, the expanding café culture and the rise of specialty coffee shops have also contributed to the growth of the instant coffee market. Freeze-dried instant coffee is particularly appealing to consumers who appreciate the convenience of instant coffee but desire a product that closely resembles freshly brewed coffee.

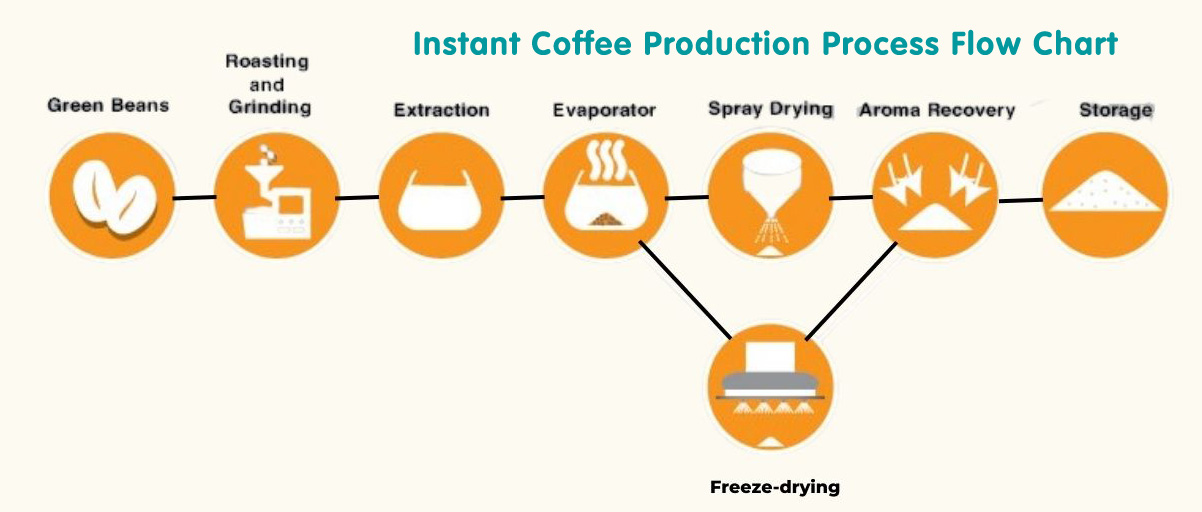

Production Process of Instant Coffee

The production of freeze-dried instant coffee involves several key steps, each critical to ensuring the final product retains its rich flavor and aroma. Here’s an overview of the main processes involved:

- Selection of Coffee Beans: The process begins with the selection of high-quality coffee beans. Arabica and Robusta are the two main types of coffee beans used in instant coffee production. Arabica beans are known for their smooth, aromatic flavor, while Robusta beans are preferred for their strong, bold taste and higher caffeine content. A blend of these beans is often used to achieve the desired flavor profile.

- Roasting: The selected coffee beans are roasted to bring out their rich flavors and aromas. The roasting process involves heating the beans to high temperatures, causing chemical changes that develop the coffee's distinctive taste. The degree of roasting (light, medium, or dark) can be adjusted to suit different flavor preferences.

- Grinding: After roasting, the coffee beans are ground into a fine powder. The grinding process is crucial as it affects the extraction of flavors during brewing. A consistent and uniform grind size ensures optimal extraction of flavors.

- Brewing: The ground coffee is then brewed using hot water to extract the soluble coffee solids. This step is similar to making a strong coffee concentrate. The brewing process is carefully controlled to ensure the extraction of the desired flavors and aromas.

- Concentration: The brewed coffee is then concentrated to remove excess water and create a thick coffee extract. This is typically done using vacuum evaporation, which involves heating the coffee under reduced pressure to evaporate the water while preserving the coffee's flavor compounds.

- Freeze-Drying: The concentrated coffee extract is frozen to very low temperatures, transforming it into solid ice. The frozen coffee is then placed in a vacuum chamber where the ice undergoes sublimation, turning directly into vapor without melting. This process removes the water content while preserving the coffee's structure and essential oils. The result is freeze-dried coffee granules that retain the rich flavor and aroma of freshly brewed coffee.

- Packaging: The final step involves packaging the freeze-dried coffee granules in airtight containers to prevent moisture absorption and preserve freshness. Packaging is critical as it ensures the product's shelf life and quality.

Equipments required for freeze-dried instant coffee manufacturing plant

Setting up a freeze-dried instant coffee manufacturing plant involves acquiring and setting up various specialized pieces of equipment, each serving a specific role in the production process. Here’s a detailed explanation of the key equipment required:

1) Coffee Roaster:

The coffee roaster is essential for roasting green coffee beans to bring out their desired flavors and aromas. During roasting, the beans undergo a series of chemical reactions that develop their characteristic taste. The roaster allows for precise control over the roasting temperature and time, ensuring that the beans are roasted to the exact specifications needed for the desired flavor profile, whether it's a light, medium, or dark roast.

2) Grinder:

After roasting, the coffee beans need to be ground into a fine powder to maximize the extraction of soluble coffee solids. A high-quality grinder ensures that the coffee is ground consistently, which is crucial for achieving uniformity in the brewing process. The grind size affects the extraction rate, and a uniform grind helps in extracting the optimal flavors from the coffee during brewing.

3) Brewing Equipment:

The brewing equipment is used to extract the soluble coffee solids from the ground coffee. This involves mixing the ground coffee with hot water to create a concentrated coffee solution. The brewing process is carefully controlled to ensure that the maximum amount of desirable flavors and aromas are extracted from the coffee grounds. This stage is similar to making a very strong coffee concentrate.

4) Evaporator:

Once the coffee is brewed, it needs to be concentrated by removing excess water. The evaporator is used for this purpose. It operates under reduced pressure to lower the boiling point of water, which allows the water to evaporate at a lower temperature. This helps in concentrating the coffee without exposing it to high temperatures that could degrade its quality. The result is a thick coffee extract that contains a high concentration of coffee solids.

5) Freeze-Dryer:

The freeze-dryer is a critical piece of equipment in the production of freeze-dried instant coffee. The concentrated coffee extract is first frozen to a very low temperature, turning it into a solid state. In the freeze-dryer, the frozen coffee is subjected to a vacuum, causing the ice to undergo sublimation. Sublimation is the process where ice turns directly into vapor without passing through the liquid stage. This method removes the water content while preserving the coffee's structure, flavor, and essential oils, resulting in freeze-dried coffee granules.

6) Packaging Machine:

The final step in the production process is packaging the freeze-dried coffee granules. The packaging machine seals the coffee in airtight containers to prevent moisture absorption and preserve freshness. Proper packaging is crucial to maintaining the quality and shelf life of the instant coffee. Airtight containers protect the coffee from environmental factors like humidity and oxygen, which can degrade its flavor and aroma over time.

Each piece of equipment plays a vital role in ensuring that the freeze-dried instant coffee is of the highest quality, retaining its rich flavor and aroma while providing the convenience that consumers expect from instant coffee products. Investing in high-quality, durable machinery is essential for achieving consistent product quality and operational efficiency in the manufacturing process.

Investing in high-quality, durable machinery is crucial for ensuring efficient operations and maintaining the quality of the freeze-dried coffee. Additionally, regular maintenance and quality checks are essential to prevent downtime and ensure consistent product quality.

Conclusion

Starting a freeze-dried instant coffee manufacturing business presents a promising opportunity, given the rising demand for high-quality instant coffee globally. The convenience, long shelf life, and ability to retain the rich flavor and aroma of freshly brewed coffee make freeze-dried coffee a preferred choice among consumers. Success in this business requires careful planning, efficient supply chain management, and strategic marketing to build a strong brand. By leveraging the growing trends in health and wellness, product innovation, and exploring export opportunities, entrepreneurs can establish a profitable and sustainable freeze-dried instant coffee business. With the right approach and a commitment to quality, the freeze-dried instant coffee business can yield substantial returns and contribute to the growing demand for premium coffee products.