LED Bulb Manufacturing - Step by Step Process and Market Forecast

In today's fast-evolving world, the lighting industry has witnessed a revolutionary transformation with the advent of LED technology. Light Emitting Diode (LED) bulbs have emerged as the forefront of energy-efficient and sustainable lighting solutions. Unlike conventional incandescent bulbs, LEDs consume significantly less energy, have a longer operational life, and offer versatile design options. This innovation aligns perfectly with the global push for environmental conservation and energy efficiency.

The LED bulb manufacturing industry has thus gained substantial traction, creating a space where innovation meets functionality. From residential spaces to industrial complexes, LEDs have permeated every corner of modern life. As the demand for energy-efficient lighting continues to soar, exploring the intricacies of LED bulb manufacturing becomes not only relevant but also indispensable for both entrepreneurs and established manufacturers.

In this comprehensive article, we will delve into the fundamental aspects of LED bulb manufacturing, ranging from the essential raw materials to the intricate production process. We will also cast a glance into the future, examining the potential trends and advancements that are set to shape the LED bulb manufacturing industry. Whether you're an aspiring entrepreneur or a curious individual keen on understanding the dynamics of this dynamic field, this article aims to illuminate the path towards a brighter, energy-efficient future through LED bulb manufacturing.

Raw materials required for LED bulb manufacturing.

Raw materials play a crucial role in the LED bulb manufacturing process, determining the quality, efficiency, and durability of the final product. LED bulbs are known for their energy efficiency, longer lifespan, and reduced environmental impact compared to traditional incandescent bulbs. To achieve these benefits, the selection of raw materials becomes paramount. Let's delve into the essential components required for LED bulb manufacturing:

LED Chips: The heart of an LED bulb is the LED chip itself. These chips are typically made from semiconductor materials such as gallium, arsenic, and phosphorous. The specific composition of these materials determines the color of the light produced by the LED. Different LED chips are used to create various color temperatures, including warm white, cool white, and daylight.

Substrate Materials: LED chips are mounted on a substrate, usually made of materials like ceramic or aluminum. These substrates provide mechanical support and thermal management to the LED chips, ensuring they operate at optimal temperatures for efficiency and longevity.

Encapsulation Materials: To protect the delicate LED chips from environmental factors, they are encapsulated in materials like epoxy resin. Encapsulation enhances the LED's durability and prevents damage from moisture, dust, and physical impact.

Phosphor Coating: Phosphor is a key material used to create white light in LED bulbs. It is applied as a coating over the LED chips to convert the blue light emitted by the chips into a broader spectrum of light that resembles natural white light.

Heat Sink: Heat sinks are essential to dissipate the heat generated by the LED chips during operation. Aluminum heat sinks are commonly used due to their excellent thermal conductivity. Efficient heat dissipation prolongs the LED bulb's lifespan and maintains its performance.

Printed Circuit Board (PCB): The PCB serves as the platform to connect various components, including the LED chips, driver circuitry, and other electronics. It also provides the electrical pathways necessary for the LED bulb's functioning.

Driver Circuitry: LED bulbs require driver circuitry to regulate the electrical current supplied to the LED chips. The driver ensures a consistent and stable flow of electricity, preventing damage to the LEDs and maintaining their efficiency.

Plastic Housing: The outer shell of the LED bulb is typically made of high-quality plastic that is heat-resistant and UV-stabilized. The housing protects the internal components, provides a base for attachment, and controls the direction of light emission.

Connectors and Wires: Wires and connectors are used to establish electrical connections between various components of the LED bulb, ensuring proper functionality.

Optical Components: Some LED bulbs, especially those designed for specific applications, may include optical components such as lenses or diffusers to control the direction and distribution of light.

Adhesives and Sealants: Various adhesives and sealants are used during the manufacturing process to securely bond components, provide insulation, and protect against moisture and contaminants.

The raw materials used in LED bulb manufacturing are carefully selected to ensure the production of energy-efficient, long-lasting, and high-performance lighting products. The advancements in LED technology and the continuous development of innovative materials contribute to the growth and evolution of the LED bulb manufacturing industry. As demand for eco-friendly and energy-efficient lighting solutions continues to rise, manufacturers are focused on refining their raw material choices to create LED bulbs that meet the highest standards of quality and sustainability.

Analysis Of Opportunities And Challenges of LED Manufacturing Business

The LED manufacturing industry has witnessed remarkable growth over the years, driven by the increasing demand for energy-efficient lighting solutions. While the industry presents numerous opportunities, it also comes with its fair share of challenges. Let's delve into the challenges and opportunities that define the landscape of the LED manufacturing industry:

Challenges:

- Cost of Initial Investment: Setting up an LED manufacturing facility requires a significant initial investment in specialized equipment and cleanroom facilities. This high upfront cost can be a barrier for new entrants in the industry.

- Quality Control: Ensuring consistent quality across LED products is challenging due to variations in raw materials, production processes, and supplier standards. Maintaining strict quality control measures is essential to prevent defects and ensure customer satisfaction.

- Rapid Technological Advancements: LED technology is evolving at a rapid pace. Manufacturers need to stay updated with the latest advancements to remain competitive. Obsolescence of equipment and techniques can lead to inefficient production processes.

- Global Competition: The LED manufacturing industry is highly competitive, with manufacturers from various regions vying for market share. Competition often leads to price wars, impacting profit margins.

- Supply Chain Disruptions: The industry heavily relies on a global supply chain for raw materials and components. Disruptions such as trade tensions, supply shortages, or geopolitical issues can affect production schedules and increase costs.

- Environmental Concerns: LED manufacturing involves the use of chemicals and materials that can have environmental impacts. Proper disposal of waste and adherence to eco-friendly practices are essential to mitigate these concerns.

Opportunities:

- Energy Efficiency and Sustainability: LED lighting is recognized for its energy efficiency and reduced environmental impact. As governments and consumers increasingly prioritize sustainability, the demand for LED lighting products is expected to rise.

- Government Initiatives: Many governments offer incentives and rebates for using energy-efficient lighting solutions. These initiatives boost the adoption of LED lighting and create a favorable market environment.

- Smart Lighting and IoT Integration: The integration of LED lighting with smart technology and the Internet of Things (IoT) presents new opportunities. Smart lighting systems that allow remote control, automation, and customization are gaining traction.

- Customization and Innovation: LED technology allows for versatile lighting solutions, including various colors, intensities, and shapes. Manufacturers can cater to diverse customer preferences and applications, leading to innovative product offerings.

- Urbanization and Infrastructure Development: Rapid urbanization and infrastructure projects worldwide drive the demand for LED lighting in residential, commercial, and industrial sectors.

- Research and Development: Ongoing research and development efforts are leading to improvements in LED efficiency, longevity, and cost-effectiveness. Manufacturers investing in R&D can gain a competitive edge.

- Green Building Standards: Green building certifications encourage the use of energy-efficient lighting systems. LED manufacturers can benefit from aligning their products with these standards.

- Global Reach: The demand for LED lighting is not limited to specific regions. Manufacturers can tap into international markets and diversify their customer base.

The LED manufacturing industry holds significant promise, driven by the global shift towards sustainable and energy-efficient lighting solutions. While challenges exist, strategic planning, innovation, and adaptability are key to navigating the industry landscape successfully. Manufacturers that prioritize quality, sustainability, and technological advancements are likely to capitalize on the opportunities and contribute to the growth of this dynamic sector.

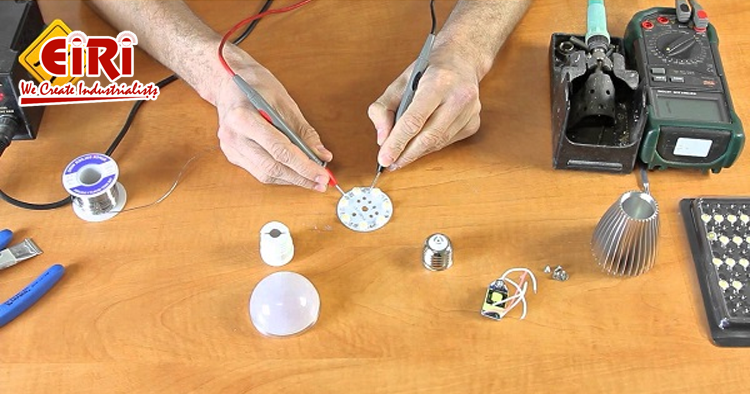

The Step-by-Step Process of Manufacturing LED Bulbs

The manufacturing process of LED bulbs involves several intricate steps that ensure the creation of energy-efficient and durable lighting solutions. In the context of the Indian market, where the demand for LED bulbs has been steadily rising due to their cost-effectiveness and energy efficiency, understanding the step-by-step process is essential. Let's delve into the detailed manufacturing process of LED bulbs in the Indian context:

1. LED Chip Fabrication:

The process begins with the fabrication of LED chips. These chips are typically made from semiconductor materials such as gallium, arsenic, and phosphide. The semiconductor material is processed to create layers with varying electrical properties. This involves advanced techniques like epitaxial growth and lithography. The result is a wafer containing numerous LED chips.

2. Wafer Testing and Sorting:

The wafer is tested to identify functioning and non-functioning LED chips. The working chips are sorted based on their color and brightness specifications. This sorting process ensures that only high-quality chips proceed to the next stage.

3. Die Bonding:

The sorted LED chips are then bonded onto a substrate, which is usually made of metal or ceramic. This substrate acts as the base for the LED bulb. The chips are bonded using conductive adhesive materials that ensure proper electrical connection.

4. Wire Bonding:

Tiny wires are attached to the LED chip's contact pads and the substrate, establishing the electrical connection. This process requires precision and is often done using automated wire bonding machines.

5. Encapsulation:

The LED chips are encapsulated to protect them from environmental factors and to enhance their light emission efficiency. This is typically done by applying a layer of epoxy resin over the LED chips. The encapsulation material can also be silicone or other advanced materials.

6. Phosphor Coating:

For white LED bulbs, a phosphor coating is applied over the LED chips. This coating converts the blue light emitted by the LED chips into a broader spectrum of colors, resulting in white light. The thickness and composition of the phosphor layer determine the color temperature of the LED bulb.

7. Base and Driver Assembly:

The LED chip assembly is then attached to the bulb's base, which is often made of plastic or metal. The driver, which regulates the electrical current supplied to the LED bulb, is also integrated into the base. The driver ensures stable performance and extends the bulb's lifespan.

8. Heat Sink Integration:

As LED bulbs emit some heat during operation, a heat sink is integrated into the design. The heat sink helps dissipate heat and prevents the LED bulb from overheating, which can affect its performance and longevity.

9. Optics and Diffusers:

Optical components such as lenses or diffusers are added to enhance light distribution and achieve the desired beam angle. These components also contribute to the aesthetics of the LED bulb.

10. Final Testing and Quality Control:

Each LED bulb undergoes rigorous testing to ensure its performance, efficiency, color accuracy, and safety. This includes tests for lumen output, color rendering, and electrical safety standards. Any defective bulbs are rejected during this stage.

11. Packaging and Distribution:

The manufactured LED bulbs are packaged in protective materials to prevent damage during transportation. Proper packaging also includes labeling with product information, energy efficiency ratings, and other relevant details. The LED bulbs are then distributed to retailers or directly to consumers.

In the Indian market, the step-by-step process of manufacturing LED bulbs aligns with global standards while catering to specific consumer demands and regulatory requirements. The process ensures the creation of high-quality, energy-efficient lighting solutions that contribute to the country's efforts towards sustainability and reduced energy consumption.

The Future Trends in the LED Bulb Manufacturing Industry

The LED bulb manufacturing industry is undergoing rapid advancements and transformative changes, driven by the pursuit of energy efficiency, environmental sustainability, and technological innovations. As the global focus on reducing energy consumption and carbon footprint intensifies, the LED bulb manufacturing sector is at the forefront of these developments. In the context of the Indian market, several trends are shaping the future of LED bulb manufacturing:

1. Enhanced Energy Efficiency:

The primary advantage of LED bulbs is their energy efficiency. As technology continues to evolve, LED manufacturers are pushing the boundaries to develop bulbs that consume even less energy while maintaining or improving light output. This trend aligns with India's commitment to energy conservation and reducing greenhouse gas emissions.

2. Smart LED Bulbs:

The integration of smart technology into LED bulbs is gaining momentum. Smart LED bulbs can be controlled remotely through smartphone apps or voice commands. They offer features like color temperature adjustment, dimming options, and even synchronization with other smart devices in a home automation system. The convenience and energy-saving potential of smart LED bulbs make them a promising trend.

3. Internet of Things (IoT) Integration:

LED bulb manufacturers are exploring IoT integration to create connected lighting systems. These systems can be integrated into smart city initiatives, commercial buildings, and residential complexes. IoT-enabled LED bulbs can be remotely monitored and controlled for optimal energy consumption and maintenance.

4. Human-Centric Lighting:

Research has shown that lighting can have a significant impact on human health and well-being. LED bulb manufacturers are focusing on developing lighting solutions that mimic natural sunlight patterns. Such human-centric lighting can enhance productivity, mood, and overall comfort, making it a sought-after trend in various settings.

5. Improved Durability and Longevity:

The longevity of LED bulbs is a key selling point. Manufacturers are continuously refining LED designs to enhance their lifespan even further. Longer-lasting LED bulbs reduce replacement frequency, resulting in less waste and a lower environmental impact.

6. Sustainable Materials and Manufacturing:

As environmental concerns grow, LED manufacturers are emphasizing sustainable practices. This includes using eco-friendly materials in manufacturing, reducing energy consumption during production, and optimizing packaging to minimize waste. Such sustainability efforts align with India's commitment to green initiatives.

7. Customized Lighting Solutions:

LED technology's versatility allows for the creation of customized lighting solutions. Manufacturers can tailor LED bulbs to specific applications, such as architectural lighting, automotive lighting, horticultural lighting, and more. This trend opens up new opportunities across various industries.

8. Focus on Aesthetics:

While functionality remains paramount, aesthetics are also gaining importance in LED bulb design. Manufacturers are focusing on creating visually appealing LED bulbs that complement interior and exterior spaces. These bulbs not only provide illumination but also enhance the overall aesthetics of the environment.

9. Cost Reduction and Affordability:

With advancements in technology and increased competition, the cost of manufacturing LED bulbs is gradually decreasing. This affordability is making LED bulbs more accessible to a broader segment of the population, which in turn drives greater adoption.

10. Government Initiatives and Incentives:

In India, government initiatives promoting energy-efficient lighting, such as the UJALA scheme, are contributing to the growth of the LED bulb manufacturing industry. Continued support from regulatory bodies and incentives can accelerate the adoption of LED technology.

The future of LED bulb manufacturing in India is poised for remarkable growth and innovation. The industry's commitment to energy efficiency, sustainability, and technological advancements aligns perfectly with the country's goals of achieving energy conservation and reducing environmental impact. As the market continues to evolve, consumers and businesses alike can look forward to a brighter and more efficient future illuminated by LED technology.