The Manufacturing of Cricket Leather Ball: Market and Future Prospects

Cricket, a sport rich in tradition and history, involves a variety of equipment, among which the leather ball stands out as a pivotal component. The craftsmanship and technology involved in the manufacturing of cricket leather balls have evolved significantly over the years, reflecting both the sport's heritage and its embrace of innovation. This article delves into the intricate process of crafting cricket leather balls, explores the current market trends, and outlines the potential future prospects for this essential piece of cricket equipment.

The Craftsmanship Behind Cricket Leather Balls

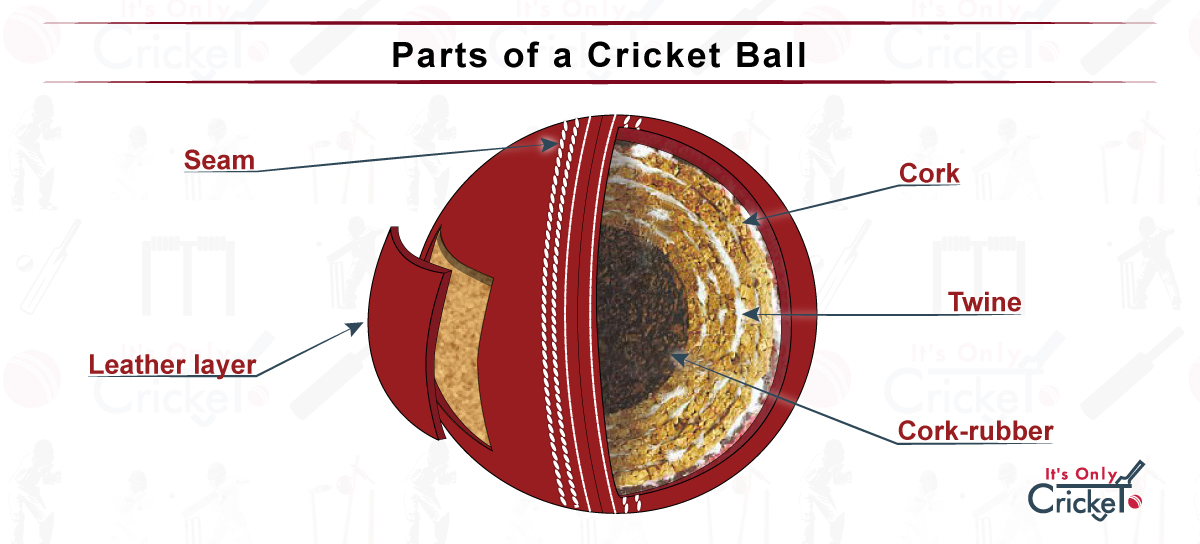

A cricket leather ball is not just an inanimate object; it encapsulates the dedication and skill of artisans who meticulously transform raw materials into a tool for exhilarating matches. The process begins with the selection of high-quality leather, typically from cowhide, that undergoes thorough quality checks. The leather's texture, durability, and consistency are paramount in ensuring a ball that can withstand the demands of the game.

The leather is then cut into panels, usually four in number, which are shaped to precision. Each panel is carefully weighed to ensure uniformity. The panels are then stitched together with utmost precision, creating the iconic cricket ball shape. The stitching process demands exceptional craftsmanship, as the ball's seams are critical to its aerodynamic properties and swing movement. Traditionally, hand-stitching was the norm, but modern production often involves the use of specialized stitching machines that maintain consistency while upholding the essence of manual artistry.

Market Trends in Cricket Leather Ball Manufacturing

The market for cricket leather balls is influenced by various factors, including international tournaments, evolving player preferences, and advancements in technology. Major cricketing events, such as the ICC Cricket World Cup and T20 leagues, drive the demand for high-quality balls that meet international standards. Additionally, the demand for cricket leather balls has extended beyond professional circles to amateur and recreational players, contributing to the overall market growth.

Technological advancements have also left their mark on ball manufacturing. Automated cutting and stitching machines have streamlined production processes, reducing the time required for ball creation. However, it's noteworthy that traditional craftsmanship is still revered by purists, and handmade balls hold a special place in the hearts of players who appreciate the game's history.

Challenges and Opportunities in the Market

The cricket leather ball market, while promising, is not without its challenges. One key challenge is ensuring the availability of high-quality leather that meets international standards. Sourcing sustainable and ethically produced leather is a concern as the industry strives to align with environmentally conscious practices.

Moreover, competition from alternative ball materials, such as synthetic options, presents a challenge to traditional leather ball manufacturers. Synthetic balls may offer durability and consistency, but the authenticity and unique characteristics of a leather ball remain irreplaceable to many cricket enthusiasts.

Future Prospects and Innovations

Looking ahead, the future prospects of cricket leather ball manufacturing appear promising. As the game continues to gain popularity globally, the demand for quality equipment is likely to rise. Innovation remains at the forefront, with manufacturers exploring ways to enhance the durability and performance of leather balls without compromising their traditional essence.

One avenue of innovation lies in the development of eco-friendly manufacturing processes and materials. Research into sustainable leather production, as well as the use of recycled materials, could address both environmental concerns and the demand for premium cricket balls.

Additionally, the integration of data-driven insights and technology could play a significant role. Smart cricket balls embedded with sensors to track spin, swing, and speed could provide players and coaches with real-time analytics, enhancing performance analysis and training methodologies.

A Business Opportunity for Enthusiasts and Innovators

Starting a cricket leather ball manufacturing business can be both profitable and rewarding, but it's important to carefully consider various factors before diving in. Here's a breakdown of the potential profitability and the type of individuals or entities that might be well-suited for starting this business:

Profitability Considerations:

- Demand and Market: The demand for high-quality cricket leather balls exists globally due to the popularity of cricket as a sport. International tournaments, leagues, schools, clubs, and recreational players all contribute to a consistent demand for cricket balls.

- Niche and Branding: Creating a niche for premium, handmade cricket leather balls can command higher prices and attract enthusiasts who value craftsmanship and authenticity.

- Innovation and Technology: Incorporating innovative materials, eco-friendly practices, and smart technology can set your brand apart and potentially justify higher pricing.

- Scalability: As you establish your business and build a reputation, you can explore scaling up production to meet larger orders and international demand.

- Market Trends: Stay updated on trends in cricket and sports equipment, such as the growing preference for sustainable and eco-friendly products.

Important Considerations:

- Quality Assurance: Quality is paramount. The cricket ball must meet international standards for size, weight, stitching, and performance to gain credibility and demand.

- Supply Chain: Establishing reliable sources for high-quality leather and materials is essential for consistent production.

- Regulations and Standards: Familiarize yourself with the regulations and standards set by cricket governing bodies, as well as any industry-specific regulations in your region.

- Competition: Research your competitors and find ways to differentiate your products through quality, innovation, or branding.

- Initial Investment: Starting a cricket leather ball manufacturing business requires investment in machinery, materials, skilled labor, and marketing.

- Sustainability: Consider incorporating sustainable practices and materials to appeal to environmentally conscious consumers.

- Market Research: Conduct thorough market research to understand the demand, pricing, and potential customer base in your target market.

Starting a cricket leather ball manufacturing business can be profitable for individuals who combine their passion for cricket with craftsmanship, innovation, and a strong understanding of market dynamics. As with any business venture, careful planning, attention to quality, and strategic differentiation are key to achieving success in this industry.

Conclusion

The manufacturing of cricket leather balls is a blend of heritage, craftsmanship, and technological progress. As cricket continues to capture the hearts of millions worldwide, the demand for quality equipment remains steadfast. The market presents both challenges and opportunities, with the need for sustainable practices and innovative approaches to cater to a diverse player base.

In the dynamic landscape of sports equipment, the cricket leather ball stands as a testament to the harmonious coexistence of tradition and innovation. Whether in the hands of professionals competing on the world stage or in the local cricket club, the leather ball remains an iconic symbol of a sport that cherishes its history while embracing the future.