Manufacturing Organic Manure: Complete Business Plan

Organic manure, also known as organic fertilizer, is gaining immense popularity among farmers and gardeners due to its numerous benefits for plant growth and soil health. As the demand for organic food and sustainable farming practices continues to rise, the manufacturing of organic manure presents a promising business opportunity. In this article, we will delve into the world of organic manure production and explore a comprehensive business plan for starting your own organic manure manufacturing venture.

The use of organic manure not only helps improve soil health but also promotes the growth of healthy plants and contributes to sustainable agricultural practices. If you are passionate about organic farming and have a keen interest in manufacturing organic manure, this comprehensive guide will provide you with valuable insights and a complete business plan to embark on a successful journey in this industry. We will delve into the various aspects of manufacturing organic manure, including the manufacturing process, market trends, growth opportunities, and the essential components of a business plan.

The manufacturing process of organic manure involves the conversion of organic waste materials, such as plant residues, animal manure, and kitchen waste, into a nutrient-rich compost that can be used to enrich soil fertility. We will explore the different methods of composting, including aerobic and anaerobic processes, and discuss the factors that contribute to the quality and effectiveness of organic manure.

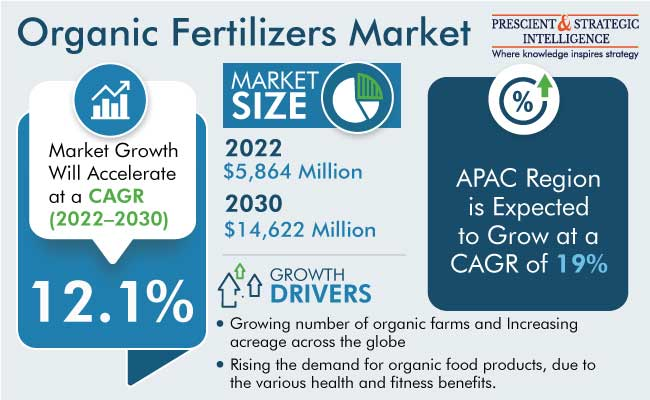

In recent years, the demand for organic manure has been on the rise due to several factors. Consumers are becoming more conscious of the impact of chemical fertilizers on the environment and human health, leading to a shift towards organic farming practices. Additionally, organic produce is gaining popularity in the market, commanding premium prices and creating a demand for organic inputs like organic manure. We will analyze the market trends and consumer preferences in the organic farming industry, highlighting the potential for growth and profitability.

To establish a successful organic manure manufacturing business, it is crucial to have a well-defined business plan. We will guide you through the essential components of a business plan, including market analysis, target market identification, financial projections, and marketing strategies. Understanding the market dynamics, competition, and regulatory requirements will enable you to make informed decisions and position your business for success.

Moreover, we will discuss the key challenges and opportunities in the organic manure manufacturing industry. These include sourcing organic waste materials, ensuring consistent product quality, managing logistics and distribution, and building strong relationships with organic farmers and retailers. By addressing these challenges and capitalizing on the opportunities, you can establish a competitive advantage and achieve sustainable growth in the market.

Market Research and Analysis: Identifying Target Customers and Market Opportunities

Before starting any business, conducting thorough market research and analysis is essential to gain insights into the target customers, understand market trends, and identify potential opportunities. In the case of manufacturing organic manure, conducting effective market research will enable you to make informed decisions and develop a successful business strategy. In this article, we will explore the importance of market research and analysis in the organic manure industry and discuss how to identify target customers and market opportunities.

Understanding the Target Customers:

The first step in market research is to identify your target customers for organic manure. Organic farming practices are gaining popularity among health-conscious individuals, environmentally conscious consumers, and those seeking sustainable agricultural solutions. Target customers may include organic farmers, home gardeners, horticulturalists, and commercial growers. By identifying the specific needs and preferences of your target customers, you can tailor your marketing strategies and product offerings accordingly.

Market Trends in Organic Farming:

Market research also involves analyzing the latest trends in organic farming. Organic produce is in high demand due to its perceived health benefits and environmental sustainability. Consumers are becoming more conscious of the impact of synthetic chemicals and pesticides on their health and the environment. They are willing to pay a premium for organic products that are free from harmful chemicals. As a manufacturer of organic manure, staying abreast of market trends in organic farming will help you align your business with consumer demands and capitalize on emerging opportunities.

Competition Analysis:

Conducting a comprehensive competition analysis is vital to understand the existing players in the organic manure market. Identify and analyze other organic manure manufacturers, their product offerings, pricing strategies, distribution channels, and marketing tactics. Assess their strengths and weaknesses to identify areas where you can differentiate your product and offer unique value to your target customers. This analysis will help you position your organic manure business effectively and develop competitive advantages.

Potential Market Segments:

Market research also involves identifying potential market segments for your organic manure. Consider the different customer segments that may benefit from using organic manure, such as organic farmers, commercial nurseries, home gardeners, and landscaping businesses. Evaluate the size of each market segment, their specific needs, and the potential demand for organic manure within those segments. This analysis will help you prioritize your target markets and develop tailored marketing strategies to reach each segment effectively.

Market research and analysis are crucial steps in establishing a successful organic manure manufacturing business. By identifying your target customers, understanding market trends, analyzing competition, and identifying potential market segments, you can position your business for growth and success. This information will guide your marketing efforts, product development, and business strategy to meet the needs of your target customers and capitalize on market opportunities. Invest time and resources in conducting comprehensive market research to lay a strong foundation for your organic manure manufacturing business.

Setting up the Manufacturing Unit: Infrastructure and Equipment Requirements

Setting up a manufacturing unit for organic manure requires careful planning and consideration of various factors. From acquiring the necessary infrastructure to selecting the right equipment and ensuring quality control measures, each step plays a crucial role in establishing a successful production facility. In this article, we will discuss the key aspects of setting up a manufacturing unit for organic manure, including infrastructure requirements, equipment needed for production, sourcing raw materials, and implementing quality control measures.

Infrastructure Requirements:

The first step in setting up a manufacturing unit is to secure the appropriate infrastructure. Depending on the scale of your operation, you may require a facility with sufficient space for production, storage, and packaging. The facility should have proper ventilation, temperature control, and access to utilities like water and electricity. Additionally, consider the need for office space, laboratory facilities for testing, and storage areas for raw materials and finished products.

Equipment Needed for Production:

To produce organic manure efficiently, you will need specific equipment tailored to the manufacturing process. This may include machinery for shredding, grinding, or pulverizing organic materials, mixing and blending equipment, and systems for composting or fermenting the raw materials. Depending on the scale of your production, you may also need packaging machines, labeling equipment, and conveyor systems for streamlined operations. It is essential to invest in reliable and high-quality equipment to ensure smooth production processes and consistent product quality.

Sourcing Raw Materials:

Organic manure is typically produced from a variety of organic materials, such as crop residues, animal waste, and green biomass. Establishing reliable sources of these raw materials is crucial for uninterrupted production. Consider establishing partnerships with local farmers, livestock breeders, or waste management companies to ensure a steady supply of organic materials. Implementing sustainable sourcing practices and maintaining proper documentation for the origin of raw materials will enhance the credibility of your organic manure.

Quality Control Measures:

Maintaining consistent quality is paramount in the manufacturing of organic manure. Implementing robust quality control measures is essential to ensure that the final product meets the required standards and regulatory compliance. This may involve conducting regular testing of raw materials and finished products to assess nutrient content, moisture levels, and absence of contaminants. Develop standard operating procedures (SOPs) for quality control, train staff members on adherence to these procedures, and establish a laboratory for conducting necessary tests. By prioritizing quality control, you can build trust among customers and create a reputation for delivering high-quality organic manure products.

Setting up a manufacturing unit for organic manure involves careful consideration of infrastructure requirements, selection of appropriate equipment, sourcing of raw materials, and implementation of quality control measures. By investing in the right infrastructure and equipment, establishing reliable raw material sources, and ensuring strict quality control, you can establish a successful manufacturing unit for organic manure. Remember to comply with relevant regulations and standards to maintain the integrity of your products. With a well-planned setup and commitment to quality, your manufacturing unit can contribute to the growth of the organic farming industry and meet the increasing demand for organic manure.

The Financial Aspect: Estimating Costs and Projecting Profitability

When considering setting up an organic manure manufacturing unit, it is crucial to conduct a thorough cost analysis. This analysis will help in determining the financial feasibility of the project and understanding the initial investment required.

The cost analysis should include various aspects such as land acquisition or leasing, construction or modification of infrastructure, procurement of machinery and equipment, labor costs, raw material sourcing, utilities expenses, licensing and permits, marketing and promotional expenses.

Once the cost analysis is complete and the production costs are determined, it is essential to develop a pricing strategy for organic manure products. Factors to consider while determining the pricing strategy include market demand and competition, production costs including overheads and maintenance fees for machinery, desired profit margins, targeted customer segment.

In addition to cost analysis and pricing strategy, financial projections play a crucial role in assessing the viability of an organic manure manufacturing unit. Financial projections involve estimating revenue generation potential based on market demand projections and pricing strategy. It also involves forecasting operating costs over a specific period including raw material sourcing costs, labor expenses, utilities bills etc. Financial projections allow for budgeting cash flow requirements as well as assessing profitability in terms of return on investment (ROI).

By conducting a comprehensive cost analysis, developing an effective pricing strategy for organic manure products and creating accurate financial projections; entrepreneurs can make informed decisions about setting up an organic manure manufacturing unit while ensuring its long-term sustainability.

Certainly! Here are the estimated financials and cost breakdowns for setting up a small-scale organic manure manufacturing plant in Indian currency (INR). Please note that these figures are for illustrative purposes and may vary based on factors such as location, scale of operations, and market conditions. It is essential to conduct a detailed feasibility study and research specific to your business plan.

Infrastructure and Equipment Costs:

Land and Building: The cost of land and building can vary significantly depending on the location and size of the manufacturing plant. As a rough estimate, it may range from ₹35 lakhs to ₹1 crore.

Machinery and Equipment: The cost of machinery and equipment required for organic manure production, such as composting machines, mixers, shredders, and packaging equipment, can range from ₹15 lakhs to ₹40 lakhs.

Raw Material Costs:

Organic Waste: The cost of procuring organic waste materials for composting can vary depending on the availability and sourcing channels. This cost can range from ₹2 lakhs to ₹6 lakhs per year, depending on the quantity and quality of the organic waste required.

Labor and Operational Expenses:

Labor Costs: The labor cost will depend on the number of employees required for various tasks, such as composting, packaging, and administrative functions. As a rough estimate, the annual labor cost can range from ₹10 lakhs to ₹20 lakhs.

Utilities: This includes expenses for electricity, water, and waste disposal. The annual utilities cost can range from ₹2 lakhs to ₹5 lakhs.

Marketing and Administrative Costs:

Marketing Expenses: The cost of marketing initiatives, including branding, advertising, and promotions, can range from ₹2 lakhs to ₹5 lakhs per year.

Administrative Expenses: This includes costs associated with licenses, permits, accounting, and legal services. The annual administrative cost can range from ₹1 lakh to ₹3 lakhs.

Revenue and Profitability:

Revenue Projection: The revenue from the sale of organic manure products will depend on factors such as pricing, market demand, and distribution channels. As an estimate, a small-scale plant can generate annual revenue ranging from ₹35 lakhs to ₹70 lakhs.

Profitability: The profitability of the plant will depend on the cost structure, pricing strategy, and operational efficiency. As a general guideline, the net profit margin for organic manure manufacturing businesses can range from 10% to 20%.

It is important to note that these estimates may vary based on specific circumstances and market conditions. Conducting a comprehensive feasibility study, market analysis, and financial modeling specific to your business plan will provide more accurate and tailored financial projections.

Contact us, to obtain precise financial estimates and validate the financial viability of your organic manure manufacturing plant in Indian currency (INR) or any other currency.

Risks and Challenges in the Organic Manure Manufacturing Business

The organic manure manufacturing business offers numerous opportunities, but like any other business, it also comes with its share of risks and challenges. It is important to be aware of these challenges and proactively address them to ensure a successful and sustainable operation. Here are some key risks and challenges to consider:

Maintaining Product Consistency:

One of the critical aspects of organic manure manufacturing is ensuring consistent product quality. Prioritizing quality control measures throughout the production process is essential to deliver a reliable and effective product to customers. This includes monitoring the composting process, using standardized formulations, and conducting regular testing to maintain product consistency.

Complying with Regulatory Standards:

The organic manure industry is subject to various regulatory standards and guidelines, especially related to organic certification, environmental protection, and waste management. It is crucial to understand and comply with these regulations to avoid legal issues and maintain the integrity of your products. This may involve obtaining organic certifications, adhering to labeling requirements, and implementing proper waste management practices.

Sourcing and Managing Raw Materials:

The availability and consistency of organic waste materials, such as agricultural residues and food waste, can pose challenges in sourcing raw materials for organic manure production. Establishing reliable supply chains, building relationships with local farmers and food processing industries, and implementing proper storage and handling practices are crucial for a consistent and sustainable supply of raw materials.

Seasonal Fluctuations and Production Planning:

The availability of organic waste materials may vary seasonally, which can impact production planning and inventory management. It is important to anticipate these fluctuations and develop strategies to manage the seasonal variations in raw material availability. This may include implementing storage facilities, establishing contracts with multiple suppliers, and developing contingency plans for lean periods.

Market Competition and Consumer Awareness:

The organic manure industry is witnessing increased competition as more players enter the market. To succeed, it is essential to differentiate your products and brand by emphasizing quality, organic certifications, and sustainability. Additionally, educating consumers about the benefits of organic manure and creating awareness about your products can help capture a larger market share.

Technological Advancements and Innovation:

Keeping up with technological advancements and embracing innovative solutions can enhance production efficiency, reduce costs, and improve product quality. Staying updated with the latest technologies, such as composting techniques, waste management systems, and automation, can give your business a competitive edge.

Economic and Market Volatility:

The organic manure industry, like any other industry, is subject to economic and market fluctuations. Changes in input costs, market demand, and consumer preferences can impact the profitability of your business. Conducting regular market research, staying informed about industry trends, and adapting your strategies accordingly can help mitigate the risks associated with market volatility.

Conclusion

Manufacturing organic manure presents a promising business opportunity in the thriving organic farming industry. With the increasing demand for organic produce and the growing awareness of sustainable agriculture practices, the market for organic manure is poised for significant growth. By understanding the manufacturing process, market trends, and key components of a business plan, you can embark on a successful journey in manufacturing organic manure and contribute to the growth of the organic farming sector.