Rubber Conveyor Belt Business - Future And Scope

Conveyor belts promote the cycle of order-to-delivery efficiency and enhance the need for production techniques and rapid delivery. They drive the global market of conveyor belts. The growth augmentation increases with automation and technology advancements coupled with eco-friendly conveyor systems. Therefore, investing in small to medium-sized conveyor systems is increasing in the market.

Insights of Rubber Conveyor Belt business

The rubber conveyor belt business is showing rising growth, and the estimated value from 2021 to 2028 is at a CAGR of 3.80%. The estimated value is $5.22 billion. The mining industry is the key driving factor for the rising growth.

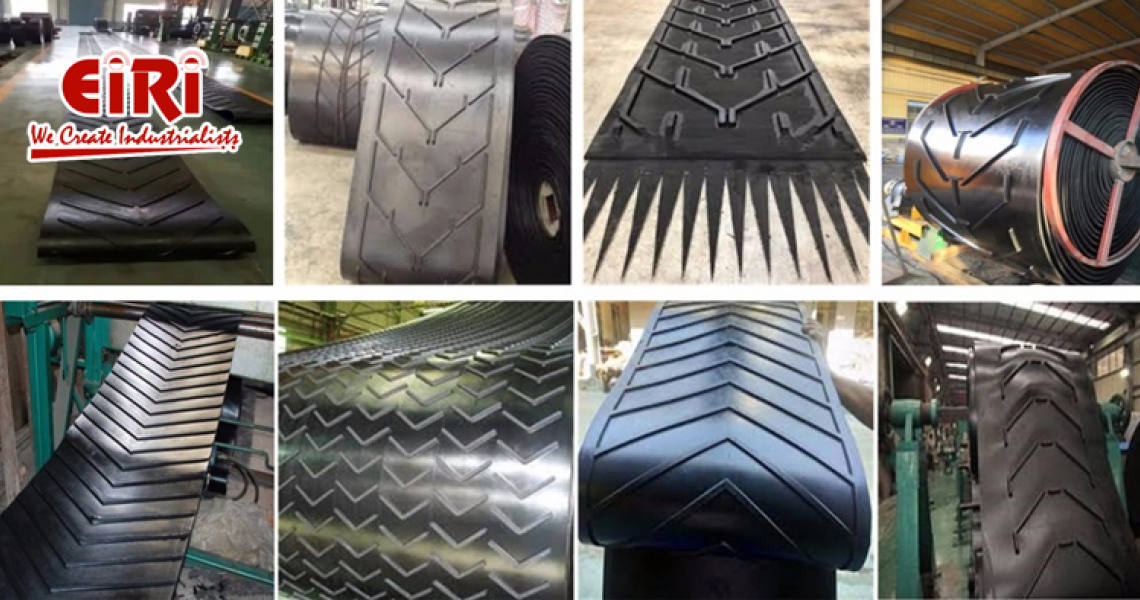

Rubber conveyor belts carry heavy loads and rocks in application industries. It is required for carrying loads, materials, components, or parts smeared with oil or oil-treated coil machinery. The belts are suitable for transportation made of resistant materials.

The power generation sector's regular development is the critical factor augmenting the growth of the market. It increases longer distances transportability, and the growth of investment in mining, food and beverage, construction, and many other activities around the globe. The increasing technological modernization and advancements are due to the emerging economies rising demand. It creates new opportunities in the market for rubber conveyor belts.

The initial cost of the setup is high, and the heavy lifting industries' maintenance costs are the major restraining factors of the market growth. The rubber conveyor belt market provides a great opportunity and scope, yet, one should know the trade regulations, the domestic market players, market regulations changes, application dominance and niches, and technological innovations.

The scope and future of the rubber conveyor belt business

The rubber conveyor belt business expects a 4.02% CAGR over the 2021 to 2026 forecast period. The market witnesses major mergers and acquisitions in shaping the landscape of the market.

The e-commerce industry is the key factor driving conveyor belt usage. The warehouses proliferate, and there is a demand for handling material by decreasing downtime. Companies in the US or US-based companies are using rubber conveyors for e-commerce fulfillment process automation.

- Conveyor belts are in various sectors owing to lightweight, high adaptability, and cost-effectiveness. The driving factor of the rubber conveyor belt business is the demand rising from the mining, power, and industrial industries. Thus, it assures the future and scope of the rubber conveyor belt business.

- All industries entail mining, manufacturing, food processing, electric vehicles, warehouses, and other material handling facilities. They seek ways to promote processes and boost demand for automation. The conveyor belt systems greatly benefit from workplace automation.

- The rubber conveyor belt business was affected due to Covid-19, the lockdown, and trade restrictions. There was a manpower shortage and a decrease in rubber prices, directly hampering rubber conveyor belt demand. However, it improved with the rise in e-commerce and is back in the market dictating the future with promising ROI.

A rubber conveyor belt helps transport goods with ease between locations. They are useful for short distances within a facility and assembly lines connecting for packing and final inspection lines. The material placed on the conveyor belt is horizontally transported or goes through an inclined slope to reach the destination. It features pulleys, two or more, assisting in rotating in continuous circles of the belt. The conveyor belts are useful in various sectors due to their lightweight, high adaptability, and cost-effectiveness. The driving factor is raising the demand for rubber conveyor belts worldwide from the mining, power, and industrial industries.

Rubber conveyor belts are oil-resistant, heat-resistant, chemical, and fire-resistant. They are in high use by end-user industries involved in Logistics, Warehouse, Manufacturing, Mining, and Metal Processing.

- End-user Industries – Logistics, Manufacturing, Mining, and different stages of Metal Processing.

- By Type – Oil-Resistant, Heat-Resistant, Chemical-Resistant, and Fire-Resistant

- Geography - Asia-Pacific, North America, Latin America, Europe, Africa, and the Middle East.

Market Trends of Rubber Conveyor Belt Business

Research experts reveal the market trends that shape the rubber conveyor belt business ranging from the mining industry to the market:

- The mining industries depend on rubber conveyor belts for materials processing transportation. The conveyor belt investment helps transport mines such as coal more cleanly and cheaply, eliminating the usage of trucks. It cuts down theft and coal diversion, thereby helping in quality maintenance.

- There will be new investments in Latin America, especially in Chile and Brazil. Latin American regions follow the trends, and today Argentina and Chile are leading lithium producers, having global reserves of more than 60%. Mining requires handling materials in larger amounts, and the conveyor system is a cost-effective and efficient solution for long distances.

A rubber conveyor belt is now coming as a fire-resistant belt helping in subterranean mines. They fulfill guidelines. The iBelt conveyor technology features added mobile functionality offering a new approach to monitoring conveyor health. This new approach is useful for customers, conveyor industry applications, and commodities.