Small-Scale Metal Fabrication: A Comprehensive Guide to Starting and Running a Successful Business

Small-scale metal fabrication is a versatile and rewarding industry, offering immense opportunities for those with the right skills, tools, and business acumen. Whether you’re an artisan creating custom metal works, a contractor fulfilling small-scale construction needs, or an entrepreneur looking to break into the manufacturing industry, metal fabrication can be both profitable and fulfilling. This article explores the ins and outs of small-scale metal fabrication, from the basics of the trade to the challenges and opportunities it presents.

Understanding Small-Scale Metal Fabrication

Metal fabrication involves the process of cutting, bending, shaping, and assembling metal components to create products or structures. In small-scale operations, this process typically focuses on custom or specialized products, rather than mass production. This scale of operation is ideal for startups, artisans, and small businesses, allowing them to cater to niche markets and offer personalized services that larger manufacturers may not provide.

Types of Metal Fabrication

Small-scale metal fabrication can encompass a wide range of activities, including:

1. Custom Metalwork:

This includes the creation of bespoke metal products such as furniture, decorative items, and architectural features. Custom metalwork often involves close collaboration with clients to design and produce unique pieces tailored to their specifications.

2. Repair and Restoration:

Small-scale fabricators often provide repair and restoration services for metal structures, machinery, and tools. This could involve anything from fixing a broken gate to restoring antique metalwork to its former glory.

3. Metal Art and Sculptures:

Artisans and artists use metal fabrication techniques to create sculptures and other art pieces. This niche allows for creative expression and can be highly rewarding, both artistically and financially.

4. Prototyping:

For inventors and small manufacturers, metal fabricators play a crucial role in creating prototypes of new products. This requires precision and skill, as the prototype must closely resemble the final product.

5. Fabrication for Construction:

This includes the creation of metal components used in construction, such as brackets, supports, railings, and structural elements. Small-scale fabricators may work on residential or small commercial projects, providing custom solutions that larger fabricators may overlook.

The Metal Fabrication Process

The metal fabrication process generally involves several key steps:

1. Designing:

The first step in metal fabrication is designing the product or component. This can be done using traditional sketching methods or with the aid of computer-aided design (CAD) software. For custom projects, the design phase often involves close collaboration with the client to ensure the final product meets their needs.

2. Cutting:

Once the design is finalized, the metal is cut into the required shapes. Cutting can be done using various methods, including manual techniques like shearing or advanced methods like laser cutting or plasma cutting. Each method has its advantages depending on the precision required and the type of metal being used.

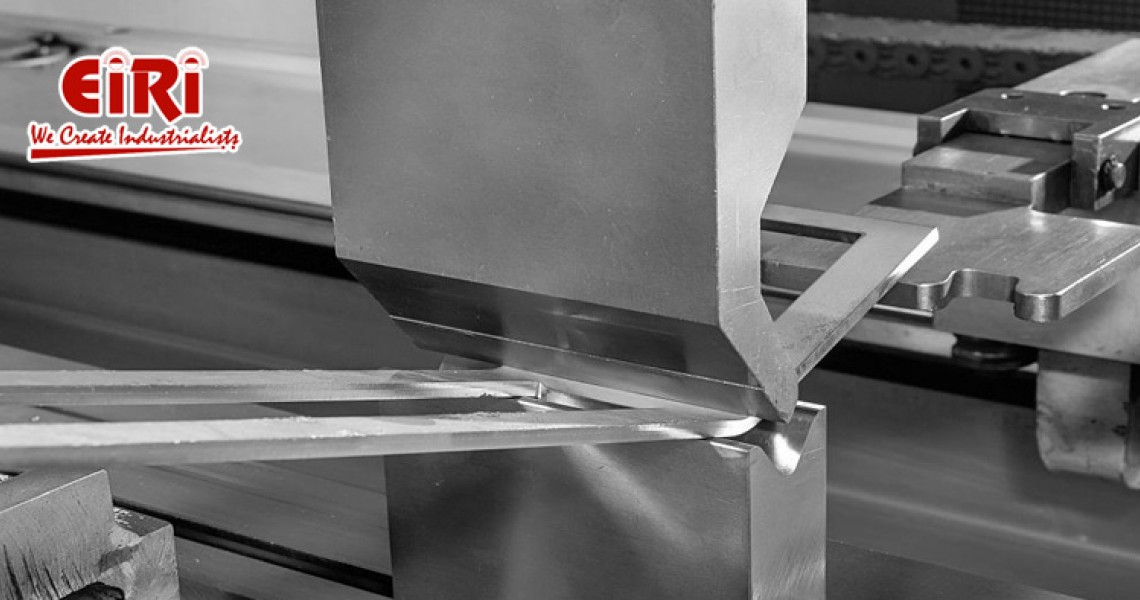

3. Bending:

After cutting, the metal may need to be bent or shaped to fit the design specifications. This is typically done using press brakes, which apply force to bend the metal at specific angles. For more intricate designs, hand tools or specialized bending equipment may be used.

4. Assembling:

The next step is assembling the cut and shaped metal pieces. This can involve welding, riveting, or using adhesives to join the pieces together. Welding is the most common method, providing a strong and durable bond between metal components. The assembler must ensure that all parts fit together precisely to create a stable and functional product.

5. Finishing:

The final step in the fabrication process is finishing. This can include polishing, painting, powder coating, or applying protective coatings to enhance the appearance and durability of the metal product. Finishing not only improves the aesthetic appeal but also protects the metal from corrosion and wear, ensuring a longer lifespan.

Starting a Small-Scale Metal Fabrication Business

1. Acquiring Skills and Training:

Before starting a metal fabrication business, it’s crucial to acquire the necessary skills and training. This can be achieved through formal education, apprenticeships, or on-the-job training. Understanding different metals, fabrication techniques, and safety protocols is essential for producing high-quality work. Additionally, business skills such as project management, customer relations, and financial management are important for running a successful business.

2. Setting Up a Workshop:

A well-equipped workshop is the backbone of a metal fabrication business. The size and scope of your workshop will depend on the type of projects you plan to undertake. At a minimum, you will need basic tools such as saws, grinders, welding equipment, and measuring instruments. For more advanced fabrication, you may need CNC machines, press brakes, and laser cutters. It’s also important to ensure that your workshop meets safety standards and is equipped with proper ventilation, fire safety measures, and protective gear.

3. Sourcing Materials:

The quality of your finished products will depend largely on the materials you use. Building relationships with reliable suppliers is crucial for sourcing high-quality metals at competitive prices. Depending on your focus, you may need a range of metals, including steel, aluminum, copper, and brass. It’s also important to keep an inventory of essential supplies such as welding rods, fasteners, and coatings.

4. Building a Customer Base:

To succeed in the metal fabrication business, you need to build a strong customer base. Start by identifying your target market—whether it’s local businesses, contractors, or individual clients. Networking, online marketing, and word-of-mouth referrals are effective ways to attract customers. Building a portfolio of your work, either through a website or physical samples, can help demonstrate your capabilities and attract new clients.

5. Pricing and Quotations:

Pricing your services appropriately is key to maintaining profitability while remaining competitive. Your pricing should take into account the cost of materials, labor, overhead, and the time required to complete each project. Providing detailed quotations to clients helps manage expectations and ensures that both parties understand the scope of the project. Transparency in pricing can build trust and lead to repeat business.

Challenges and Opportunities in Small-Scale Metal Fabrication

1. Competition:

The metal fabrication industry is competitive, with many players ranging from large manufacturers to small workshops. To stand out, small-scale fabricators need to offer something unique—whether it’s exceptional craftsmanship, fast turnaround times, or specialized services. Building a strong brand and reputation for quality can help attract loyal customers.

2. Technological Advances:

Advances in technology, such as CNC machining, 3D printing, and automated welding, are transforming the metal fabrication industry. While these technologies can enhance efficiency and precision, they also require significant investment. Small-scale fabricators must balance the need to stay competitive with the costs of adopting new technologies.

3. Economic Factors:

The demand for metal fabrication services can be influenced by economic factors, such as fluctuations in the construction industry or changes in material costs. Small-scale fabricators need to be adaptable and capable of diversifying their services to weather economic downturns. Keeping a close eye on market trends and being proactive in adjusting your business strategy can help mitigate the impact of economic challenges.

4. Regulatory Compliance:

Compliance with industry regulations and safety standards is essential in metal fabrication. This includes adhering to occupational health and safety guidelines, environmental regulations, and quality standards. Failure to comply can result in fines, legal issues, and damage to your business reputation. Staying informed about regulatory changes and implementing best practices in your workshop is crucial for long-term success.

5. Sustainability:

Sustainability is becoming increasingly important in the metal fabrication industry. Clients and consumers are more conscious of environmental impact, and there is growing demand for sustainable practices. This includes using recycled materials, minimizing waste, and reducing energy consumption in the fabrication process. Adopting sustainable practices can not only reduce costs but also enhance your brand’s appeal to environmentally conscious customers.

The Future of Small-Scale Metal Fabrication

The future of small-scale metal fabrication is bright, with numerous opportunities for growth and innovation. As industries evolve and new technologies emerge, the demand for custom, high-quality metal products is likely to increase. Small-scale fabricators who are willing to embrace new technologies, invest in skill development, and adapt to changing market conditions will be well-positioned to succeed.

Moreover, the trend towards personalization and customization in consumer products presents significant opportunities for small-scale fabricators. Customers are increasingly seeking unique, tailor-made solutions that reflect their individual preferences, and small-scale operations are ideally suited to meet this demand.

In conclusion, small-scale metal fabrication is a dynamic and rewarding industry, offering opportunities for creative expression, technical innovation, and business growth. By mastering the craft, investing in the right tools and technologies, and building strong relationships with customers, small-scale fabricators can carve out a successful niche in this competitive industry. Whether you’re just starting out or looking to expand your existing business, the key to success lies in a commitment to quality, continuous learning, and adaptability.