Sorbitol Manufacturing: A Comprehensive Overview

Sorbitol, also known as glucitol, is a sugar alcohol commonly used as a sugar substitute in various industries, including food, pharmaceuticals, cosmetics, and personal care products. It is a versatile ingredient with applications ranging from sweeteners to moisturizers, making it a valuable product in the global market. The demand for sorbitol has been growing steadily due to its low-calorie content and its use as a functional ingredient in various products. In this article, we will explore the sorbitol manufacturing process, the key raw materials involved, the types of sorbitol, and its applications across different industries.

Raw Materials Used in Sorbitol Production

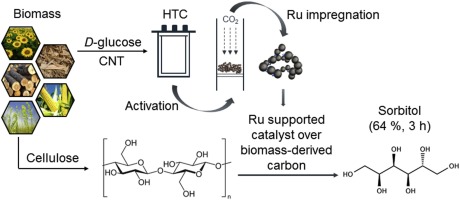

The primary raw material used in the production of sorbitol is glucose, which is derived from starch. Corn, wheat, and potatoes are the most common sources of starch used in the manufacturing process. The choice of starch source depends on regional availability and cost considerations. In some cases, dextrose (another form of glucose) may also be used as a starting material.

The production of sorbitol involves the hydrogenation of glucose. This process requires a catalyst, typically nickel, which facilitates the conversion of glucose to sorbitol. Water and hydrogen gas are also essential components of the manufacturing process.

Manufacturing Process of Sorbitol

The production of sorbitol can be divided into several stages, each critical to achieving the desired quality and purity of the final product. The process generally involves the following steps:

Starch Hydrolysis:

The first step in sorbitol manufacturing is the hydrolysis of starch to produce glucose. This is achieved by treating the starch with enzymes or acids that break down the long chains of starch molecules into simpler glucose units. The choice between enzymatic or acid hydrolysis depends on factors such as cost, efficiency, and environmental impact. Enzymatic hydrolysis is often preferred due to its higher specificity and lower energy requirements.

Glucose Purification:

After hydrolysis, the glucose solution contains impurities that need to be removed. The purification process involves filtration, decolorization, and ion exchange. These steps help in removing unwanted substances such as proteins, fats, and colorants from the glucose solution, ensuring that it meets the required quality standards for further processing.

Hydrogenation:

The purified glucose solution is then subjected to hydrogenation, where it is converted into sorbitol. This process takes place in a hydrogenation reactor, where the glucose is mixed with water and exposed to hydrogen gas in the presence of a nickel catalyst. The hydrogenation reaction reduces the carbonyl group in glucose to a hydroxyl group, resulting in the formation of sorbitol. The reaction conditions, including temperature, pressure, and catalyst concentration, are carefully controlled to optimize the yield and quality of sorbitol.

Sorbitol Purification:

After hydrogenation, the sorbitol solution is subjected to a series of purification steps to remove any remaining impurities and by-products. These steps typically include filtration, ion exchange, and evaporation. The purified sorbitol solution is then concentrated to the desired level, depending on the intended application. The final product can be obtained in liquid or crystalline form, with varying degrees of purity and concentration.

Drying and Crystallization (if required):

For certain applications, sorbitol is required in crystalline form. In such cases, the concentrated sorbitol solution is subjected to a drying and crystallization process. This involves cooling the solution under controlled conditions to promote the formation of sorbitol crystals. The crystals are then separated from the liquid and further dried to obtain the final product.

Types of Sorbitol

Sorbitol is available in different forms, each with specific properties and applications. The two main types of sorbitol are:

Liquid Sorbitol:

Liquid sorbitol is a clear, viscous solution with a high water content. It is widely used in the food and beverage industry as a sweetener, humectant, and stabilizer. Liquid sorbitol is also used in pharmaceuticals, cosmetics, and personal care products for its moisturizing and emollient properties.

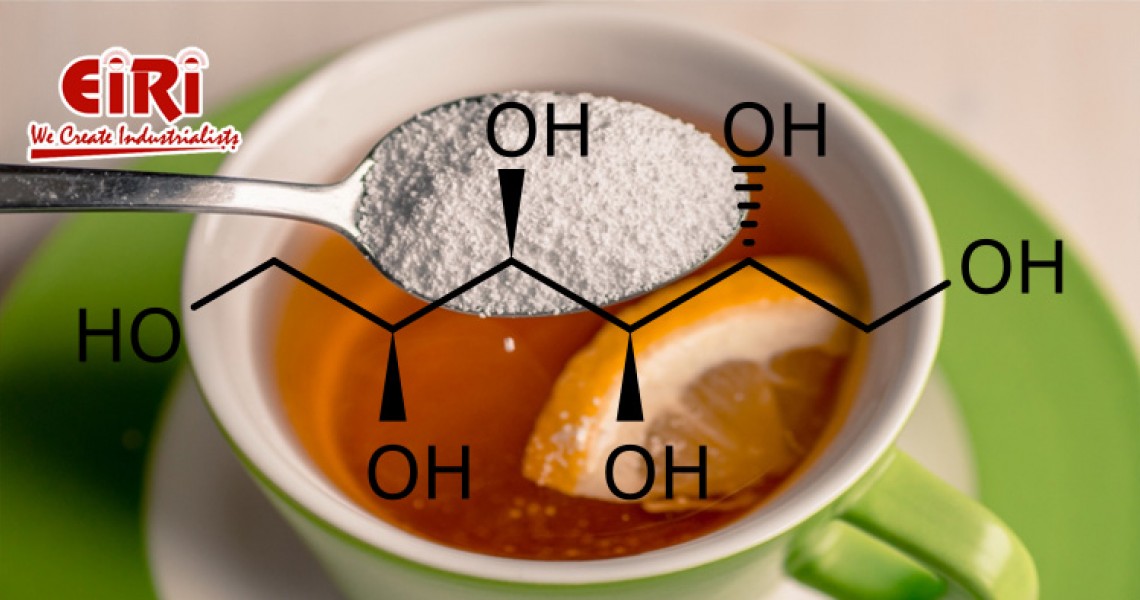

Crystalline Sorbitol:

Crystalline sorbitol is a white, odorless powder with a sweet taste. It is used in the food industry as a bulking agent, especially in sugar-free and low-calorie products. Crystalline sorbitol is also used in the pharmaceutical industry as an excipient in tablet formulations, where it acts as a filler and binder.

Applications of Sorbitol

Sorbitol's versatility makes it a valuable ingredient in various industries. Some of the key applications of sorbitol include:

Food and Beverage Industry:

Sorbitol is widely used as a sugar substitute in sugar-free and low-calorie products, such as chewing gums, candies, and baked goods. It provides a similar sweetness to sugar but with fewer calories, making it an ideal ingredient for weight management products. Sorbitol also acts as a humectant, helping to retain moisture in food products, thereby extending their shelf life.

Pharmaceutical Industry:

In the pharmaceutical industry, sorbitol is used as an excipient in the formulation of tablets, syrups, and lozenges. Its sweet taste and non-cariogenic properties make it suitable for use in oral care products, such as toothpaste and mouthwashes. Sorbitol is also used as a stabilizer in liquid medications and as a laxative in certain formulations.

Cosmetics and Personal Care Industry:

Sorbitol is a popular ingredient in cosmetics and personal care products due to its moisturizing and skin-conditioning properties. It is commonly found in lotions, creams, shampoos, and toothpaste, where it helps to retain moisture and improve the texture of the product. Sorbitol's non-irritating nature makes it suitable for use in products for sensitive skin.

Industrial Applications:

Sorbitol is used in the production of surfactants, resins, and plasticizers in the industrial sector. It is also used as a feedstock for the production of other chemicals, such as isosorbide and propylene glycol, which have applications in various industries, including automotive, construction, and packaging.

Market Outlook and Future Trends

The global sorbitol market is expected to grow steadily in the coming years, driven by the increasing demand for sugar substitutes and functional ingredients in the food and beverage industry. The growing awareness of health and wellness among consumers is also expected to boost the demand for low-calorie and sugar-free products, further driving the demand for sorbitol.

In addition, the expanding applications of sorbitol in the pharmaceutical, cosmetics, and industrial sectors are expected to contribute to market growth. The development of new technologies for the production of sorbitol, such as enzymatic hydrolysis and biocatalysis, is likely to improve the efficiency and sustainability of the manufacturing process.

However, the market faces challenges, such as fluctuations in raw material prices and competition from other sugar substitutes, such as xylitol and maltitol. Manufacturers will need to focus on innovation, cost optimization, and product differentiation to maintain their competitive edge in the market.

Conclusion

Sorbitol manufacturing is a complex process that involves the conversion of glucose to sorbitol through hydrogenation. The versatility of sorbitol makes it a valuable ingredient in various industries, including food and beverage, pharmaceuticals, cosmetics, and industrial applications. With the growing demand for sugar substitutes and functional ingredients, the sorbitol market is poised for steady growth in the coming years. As consumer preferences shift towards healthier and more sustainable products, the importance of sorbitol in the global market is expected to increase, making it a promising area for investment and development.