The Future of Biomass Briquettes Manufacturing: Opportunities and Growth Prospects

In recent years, the global focus on renewable energy and sustainable manufacturing practices has led to a surge in demand for biomass briquettes. Biomass briquettes, made from organic materials such as agricultural waste, wood residues, and other biomass sources, have emerged as a viable alternative to traditional fossil fuels. This environmentally friendly fuel offers numerous benefits, including reduced carbon emissions, cost-effectiveness, and efficient combustion.

The biomass briquette industry is poised for significant growth as governments, industries, and consumers worldwide prioritize sustainable energy solutions. As the world transitions towards cleaner and greener fuel options, biomass briquettes are gaining traction as a renewable energy source with wide-ranging applications.

The market demand for biomass briquettes is being driven by several factors. Firstly, the increasing awareness of the environmental impact of fossil fuels has led to a growing demand for cleaner alternatives. Biomass briquettes offer a sustainable and carbon-neutral fuel option, helping to reduce greenhouse gas emissions and combat climate change.

Additionally, the versatility of biomass briquettes contributes to their market appeal. These briquettes can be used for various applications, including heating, cooking, and electricity generation. Industries such as power plants, commercial kitchens, and residential heating systems are increasingly adopting biomass briquettes as a reliable and efficient energy source.

Moreover, the manufacturing process of biomass briquettes presents opportunities for rural development and job creation. The abundance of biomass resources in agricultural and forestry sectors provides a sustainable feedstock for briquette production, contributing to the growth of local economies and reducing dependence on imported fossil fuels.

Looking ahead, the future of biomass briquettes manufacturing holds immense potential. The industry is expected to witness steady growth as governments worldwide implement policies and incentives to promote renewable energy sources. Technological advancements in biomass processing and briquette manufacturing are further enhancing production efficiency and quality.

In this article, we will delve deeper into the biomass briquette industry, exploring the current market landscape, growth prospects, and the opportunities it presents. We will examine the key drivers behind the market demand, the manufacturing process of biomass briquettes, and the challenges and opportunities that lie ahead.

The Advantages and Benefits of Biomass Briquettes

Biomass briquettes have emerged as a sustainable and eco-friendly alternative to traditional fossil fuels. Made from organic materials such as agricultural waste, wood residues, and other biomass sources, these compact, solid fuel blocks offer numerous advantages and benefits. As the world seeks cleaner and greener energy solutions, biomass briquettes have gained significant attention for their positive environmental impact and versatile applications.

One of the key advantages of biomass briquettes is their contribution to reducing carbon emissions. When compared to fossil fuels, biomass briquettes have lower net carbon dioxide emissions, as the carbon released during their combustion is offset by the carbon absorbed during the growth of the biomass feedstock. This makes biomass briquettes a carbon-neutral fuel option and an effective tool in combating climate change.

Another notable benefit of biomass briquettes is their cost-effectiveness. Biomass feedstock, such as agricultural residues or wood waste, is often available at low or even zero cost, making it a readily accessible and affordable raw material for briquette production. Additionally, the manufacturing process of biomass briquettes can be relatively simple and efficient, further contributing to cost savings.

Biomass briquettes also offer excellent combustion efficiency, resulting in high heat output and prolonged burn times. The dense composition of the briquettes ensures a consistent and controlled burn, allowing for efficient energy conversion. This makes biomass briquettes an ideal choice for various heating applications, including residential heating, industrial boilers, and commercial cooking.

The versatility of biomass briquettes is another compelling advantage. These briquettes can be tailored to specific energy needs, with varying sizes and compositions to suit different applications. They can be used in a wide range of industries, including power generation, cooking, and even as a substitute for charcoal in barbecues and grills.

Furthermore, biomass briquettes contribute to waste management and sustainable resource utilization. By utilizing agricultural residues and wood waste, they help reduce the environmental burden of these materials and prevent their accumulation in landfills. This promotes a circular economy and ensures the efficient use of available biomass resources.

The Process of Biomass Briquette Manufacturing: From Raw Material to Finished Product

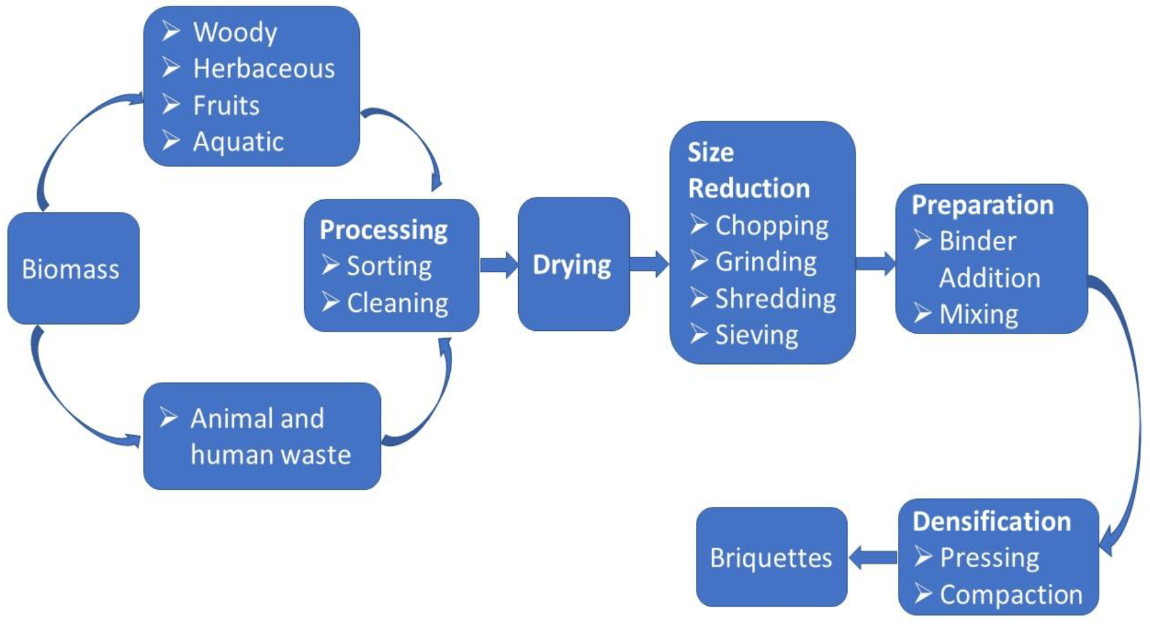

Biomass briquettes are an increasingly popular and sustainable source of energy, offering a cleaner and greener alternative to traditional fossil fuels. The manufacturing process of biomass briquettes involves several key steps, from sourcing the raw materials to transforming them into the final product. Let's explore the process in detail.

Raw Material Selection:

The first step in biomass briquette manufacturing is selecting suitable raw materials. Common biomass feedstocks include agricultural residues (such as crop straw, husks, and shells), wood waste (sawdust, wood chips), and other organic materials. The choice of raw material depends on its availability, cost, energy content, and compatibility with the briquette making process.

Raw Material Preparation:

The selected raw materials are processed to ensure their suitability for briquette production. This may involve grinding, shredding, or drying the biomass feedstock to reduce its moisture content and size. Proper preparation of the raw materials helps enhance the briquette's density, combustion efficiency, and overall quality.

Briquette Making Machines:

Once the raw materials are prepared, they are fed into briquette making machines. These machines come in various types and designs, but they all serve the same purpose of compressing the biomass feedstock to form solid briquettes. The machines apply pressure and heat to bind the biomass particles together, resulting in compact and uniform briquettes.

Binding Agents:

In some cases, binding agents are added to the biomass feedstock to improve the briquette's cohesion and stability. Common binding agents include starch, lignin, molasses, and other natural substances. These agents help hold the biomass particles together during the compression process and ensure the briquettes maintain their shape and integrity.

Briquette Drying:

After the briquettes are formed, they need to be properly dried to reduce their moisture content. Drying can be done through natural air drying or using mechanical drying techniques. Proper drying is essential to enhance the briquettes' combustion efficiency and prevent spoilage or degradation during storage and transportation.

Quality Control:

Quality control measures are implemented throughout the manufacturing process to ensure the final product meets the desired standards. This includes checking the briquettes for size, shape, density, moisture content, and overall quality. Any substandard briquettes are discarded or reprocessed to maintain consistency and reliability.

Packaging and Distribution:

Once the briquettes pass quality control, they are packaged and prepared for distribution. Packaging can be done in various forms, such as bags, boxes, or bulk packaging, depending on the target market and customer requirements. Proper packaging ensures the briquettes remain intact and protected during storage and transportation.

The process of biomass briquette manufacturing requires specialized knowledge, equipment, and expertise. However, with advancements in technology and the availability of briquette making machines, it has become more accessible for businesses and individuals to venture into this industry.

Biomass briquettes offer a sustainable and renewable energy source, reducing reliance on fossil fuels and contributing to environmental preservation. They find applications in various industries, including power generation, cooking, heating, and even as a source of fuel in certain industrial processes.

As the demand for clean and renewable energy continues to rise, the future of biomass briquette manufacturing looks promising. With advancements in biomass processing technologies and increased awareness of the environmental benefits, the industry is poised for growth and expansion.

The process of biomass briquette manufacturing involves selecting suitable raw materials, preparing them, using briquette making machines, adding binding agents if necessary, drying the briquettes, implementing quality control measures, and packaging the final product. This process transforms organic waste materials into valuable and eco-friendly briquettes, offering a sustainable solution for energy needs.

In addition to their environmental and economic advantages, biomass briquettes also offer social benefits. The local production of briquettes can create employment opportunities, particularly in rural areas where biomass feedstock is abundant. This can contribute to rural development, poverty alleviation, and the empowerment of local communities.

The Growing Demand for Biomass Briquettes in Various Industries

Biomass briquettes have gained significant recognition as a sustainable and eco-friendly alternative to traditional fossil fuels. With their numerous advantages and versatility, biomass briquettes are finding increasing demand in various industries. Let's explore the growing applications of biomass briquettes in different sectors.

Power Generation Sector:

Biomass briquettes are widely used in the power generation industry as a renewable energy source. They can be used in biomass power plants to produce electricity through the combustion process. The high energy content and consistent burning properties of biomass briquettes make them an ideal fuel for power generation, reducing reliance on fossil fuels and minimizing carbon emissions.

Cooking and Heating Industry:

Biomass briquettes serve as an efficient fuel source for cooking and heating purposes. They are extensively used in households, hotels, restaurants, and other establishments where clean and affordable cooking fuel is required. Biomass briquettes provide a steady and prolonged heat output, making them suitable for cooking, heating water, and space heating applications.

Industrial Applications:

Biomass briquettes find applications in various industries as a cost-effective and sustainable fuel source. They are used in industries such as ceramics, textile, paper, food processing, and brick kilns, among others. Biomass briquettes offer reliable and consistent heat supply, making them an attractive choice for industrial processes that require high temperatures or steam generation.

Alternative to Fossil Fuels:

The increasing environmental concerns and the need to reduce greenhouse gas emissions have led to a growing demand for biomass briquettes as an alternative to fossil fuels. Biomass briquettes are carbon-neutral, meaning they do not contribute to the net increase in atmospheric carbon dioxide levels. Switching to biomass briquettes helps industries reduce their carbon footprint and comply with environmental regulations.

The growing demand for biomass briquettes can be attributed to several factors. First and foremost, biomass briquettes are derived from renewable sources such as agricultural residues, wood waste, and other organic materials, making them a sustainable fuel option. Additionally, biomass briquettes offer several advantages over conventional fuels, including lower emissions, higher calorific value, easy storage and transportation, and reduced ash content.

Furthermore, the availability of briquette manufacturing technology and equipment has made the production process more accessible and cost-effective. This, in turn, has contributed to the expansion of the biomass briquette market and increased adoption by various industries.

As the world continues to focus on sustainable and clean energy solutions, the demand for biomass briquettes is expected to witness significant growth. The biomass briquette industry is poised for further development, driven by government initiatives promoting renewable energy, rising environmental consciousness, and the need for energy security.

The Role of Government Policies and Initiatives in Promoting Biomass Briquetting Industry

Government policies and initiatives play a crucial role in promoting the biomass briquetting industry in India. With a focus on renewable energy and sustainable manufacturing practices, the government has introduced several measures to support and encourage the growth of biomass briquette production. Let's explore the key aspects of government policies and initiatives in promoting the biomass briquetting industry.

Government Support for Biomass Energy Projects:

The Indian government recognizes the potential of biomass energy in meeting the country's energy needs while reducing dependency on fossil fuels. Various schemes and programs have been implemented to support biomass energy projects, including biomass briquette manufacturing. Financial assistance, grants, and subsidies are provided to entrepreneurs and businesses engaged in biomass briquetting to incentivize investment in this sector.

Subsidies and Incentives for Biomass Briquette Manufacturers:

To promote the adoption of biomass briquettes as a renewable fuel source, the government provides subsidies and incentives to biomass briquette manufacturers. These incentives help offset the initial capital investment and operational costs, making the production process more economically viable. It encourages more entrepreneurs and businesses to enter the biomass briquetting industry and contributes to its growth.

Regulatory Framework for Sustainable Manufacturing Practices:

The government has established a regulatory framework to ensure sustainable manufacturing practices in the biomass briquetting industry. This framework includes guidelines and standards for the sourcing of raw materials, production processes, and environmental compliance. It aims to promote responsible and eco-friendly manufacturing practices, ensuring that the production of biomass briquettes is carried out in an environmentally sustainable manner.

Awareness Programs and Capacity Building:

The government conducts awareness programs and capacity building initiatives to educate stakeholders about the benefits of biomass briquettes and the importance of sustainable energy practices. These programs help create awareness among potential entrepreneurs, investors, and consumers about the advantages of biomass briquettes as a renewable and cleaner fuel source. They also provide training and skill development opportunities to individuals interested in entering the biomass briquetting industry.

The role of government policies and initiatives in promoting the biomass briquetting industry in India cannot be overstated. These measures have created a favorable environment for investment, innovation, and growth in the sector. They have encouraged entrepreneurship, fostered technological advancements, and facilitated the development of a robust supply chain for biomass briquettes.

The government's support has not only contributed to the expansion of the biomass briquetting industry but also aligned with India's sustainable development goals and commitment to reducing carbon emissions. By promoting the use of biomass briquettes, the government aims to achieve a greener and cleaner energy landscape, reduce dependence on fossil fuels, and mitigate the impact of climate change.

The Future Growth Potential of the Biomass Briquette Industry

The biomass briquette industry is experiencing significant growth and holds immense potential for the future. As the world shifts towards renewable energy sources and sustainable practices, biomass briquettes have emerged as a promising alternative to traditional fossil fuels. Let's explore the future growth potential of the biomass briquette industry and the factors contributing to its success.

Increasing Demand for Renewable Energy:

With growing concerns about climate change and the need to reduce greenhouse gas emissions, there is a rising demand for renewable energy sources. Biomass briquettes, made from organic waste materials such as agricultural residues, forestry residues, and biomass feedstock, offer a renewable and carbon-neutral fuel option. As countries strive to achieve their renewable energy targets, the demand for biomass briquettes is expected to witness significant growth.

Favorable Government Policies and Incentives:

Governments worldwide are implementing supportive policies and providing incentives to promote the use of biomass briquettes as a renewable energy source. These policies include financial assistance, tax benefits, and subsidies for biomass briquette production and consumption. Such initiatives create a conducive environment for the growth of the biomass briquette industry and attract investments in this sector.

Technological Advancements:

Continuous advancements in biomass briquette production technology are improving the efficiency and cost-effectiveness of the manufacturing process. Innovations in briquette-making machines, drying systems, and biomass densification techniques have enhanced the quality and consistency of biomass briquettes. These technological developments are driving the growth of the industry by enabling manufacturers to produce high-quality briquettes at a competitive price.

Environmental Benefits and Sustainable Practices:

The use of biomass briquettes as a fuel source offers several environmental benefits. Biomass briquettes have lower emissions of greenhouse gases compared to fossil fuels, contributing to reduced carbon footprint and improved air quality. Additionally, the utilization of organic waste materials for briquette production promotes sustainable waste management practices, reducing the environmental impact of agricultural and forestry residues.

Diverse Applications and Market Expansion:

The applications of biomass briquettes extend beyond energy generation. They are used as a feedstock in various industries, including thermal power plants, brick kilns, cooking and heating applications, and industrial boilers. As the awareness and acceptance of biomass briquettes increase, new market opportunities and applications are emerging. This diversification of applications is expected to drive the growth of the biomass briquette industry.

Focus on Circular Economy and Waste-to-Energy Concepts:

The biomass briquette industry aligns with the principles of a circular economy and the concept of waste-to-energy conversion. By utilizing agricultural residues, forest waste, and other organic materials, biomass briquettes contribute to reducing waste and promoting the efficient use of resources. This aspect of sustainability and waste management resonates with the growing focus on circular economy practices worldwide.

International Market Opportunities:

The global market for biomass briquettes is expanding as more countries recognize the importance of renewable energy and sustainable practices. International collaborations and trade agreements provide opportunities for biomass briquette manufacturers to tap into new markets and expand their reach. This globalization of the industry opens doors to export opportunities and enhances the growth potential for the biomass briquette industry.

In conclusion, the future of the biomass briquette industry is promising, driven by the increasing demand for renewable energy, supportive government policies, technological advancements, environmental benefits, and market expansion. As the world transitions towards a greener and more sustainable future, biomass briquettes are poised to play a vital role in the energy mix. The industry's growth potential presents significant opportunities for entrepreneurs, investors, and stakeholders to contribute to the renewable energy transition and foster a cleaner and more sustainable world.