The Growing Market for Silica: Applications, Manufacturing Process, and Market Forecast

Silica, a versatile and widely used mineral, has gained significant traction in various industries due to its unique properties and applications. This article explores the growing market for silica, delving into its diverse applications, the manufacturing process, and a market forecast for the future.

Understanding Silica:

Silica, also known as silicon dioxide (SiO2), is a naturally occurring mineral found in abundance in the Earth's crust. It exists in different forms, including crystalline and amorphous silica, each with its distinct characteristics. Silica is known for its high hardness, chemical stability, and thermal resistance, making it an essential component in numerous industrial applications.

Applications of Silica:

2.1. Construction Industry:

Silica plays a vital role in the construction sector, primarily in the production of concrete, cement, and other building materials. Its fine particle size and pozzolanic properties enhance the strength, durability, and workability of concrete structures.

2.2. Glass Manufacturing:

Silica is a fundamental ingredient in glass production. It provides transparency, chemical durability, and thermal shock resistance to glass products. From everyday glassware to high-tech applications like optical fibers and solar panels, silica is a critical component in the glass industry.

2.3. Foundry and Metal Casting:

In foundry applications, silica sand is used as a molding material to create molds for metal casting. Its high refractory properties enable it to withstand extreme temperatures and facilitate the production of intricate metal parts.

2.4. Chemical Industry:

Silica finds its application in the chemical industry as a catalyst and adsorbent. It is used in the production of various chemicals, such as silicones, silicates, zeolites, and catalysts for petroleum refining and petrochemical processes.

Manufacturing Process of Silica:

Silica can be obtained from natural sources or synthesized through chemical processes. The primary source of silica is silica sand, which undergoes purification and refinement to meet industry specifications. The manufacturing process involves mining, washing, drying, and further processing to achieve the desired purity and particle size.

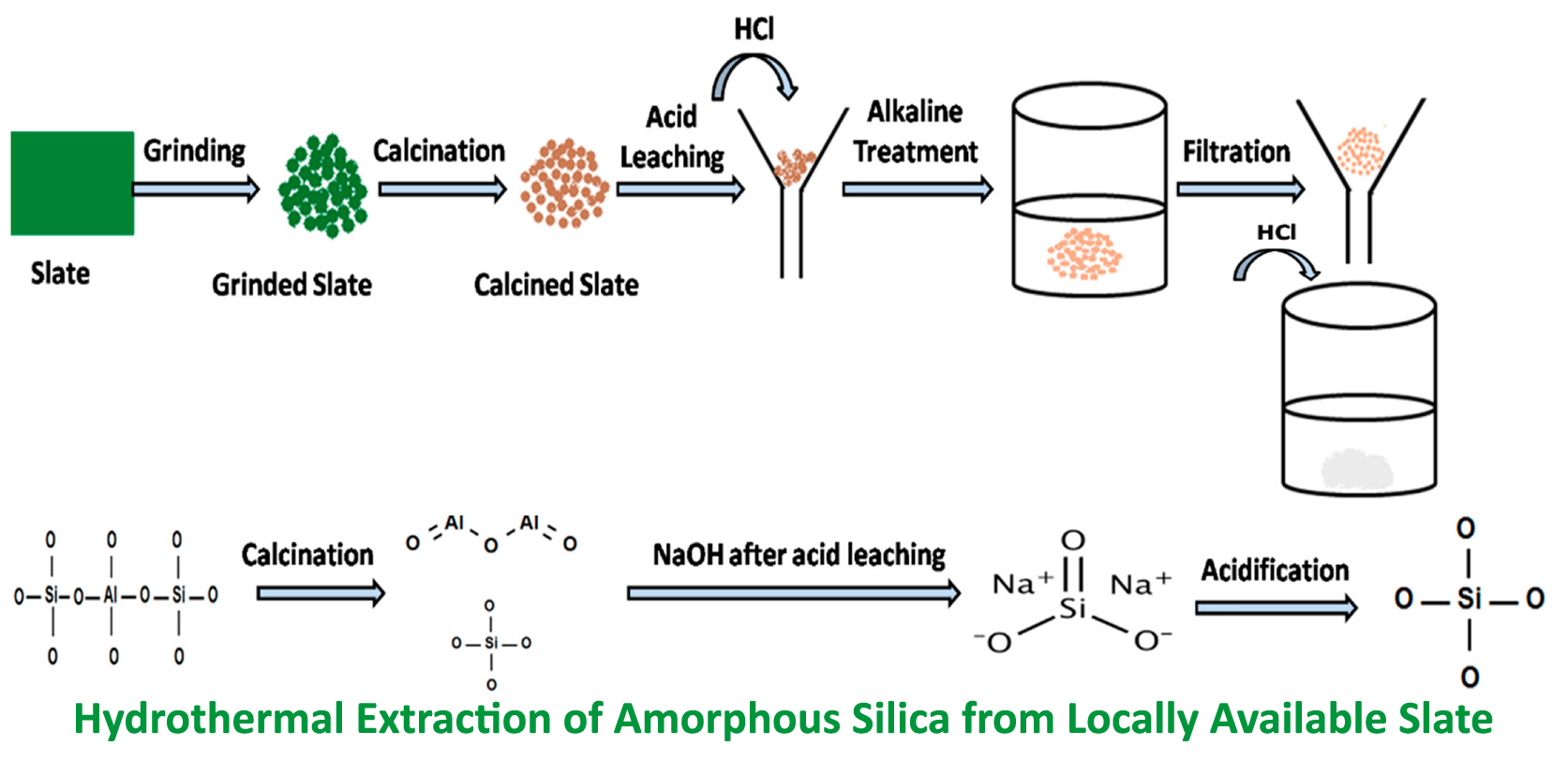

The manufacturing process of silica involves several steps that transform raw materials into the desired form. Here is an elaboration on the manufacturing process of silica:

- Extraction of Raw Materials: Silica is primarily obtained from silica sand, which is a naturally occurring mineral composed of silicon dioxide. The extraction process involves mining or quarrying silica sand deposits from the earth.

- Washing and Purification: Once the silica sand is extracted, it undergoes a washing process to remove impurities such as clay, organic matter, and iron oxide. This step ensures that the silica sand is clean and suitable for further processing.

- Crushing and Grinding: The purified silica sand is then crushed and ground into a fine powder. This process increases the surface area of the silica particles, making it easier to react with other materials during subsequent manufacturing steps.

- Chemical Treatment: Depending on the desired properties of the silica, it may undergo chemical treatment to modify its characteristics. This treatment involves adding chemicals or compounds to enhance specific properties like heat resistance, optical transparency, or electrical conductivity.

- Drying and Sintering: The treated silica powder is dried to remove any residual moisture. It is then sintered, which involves heating the silica particles to a high temperature without melting them. Sintering helps to bond the silica particles together, resulting in a solid and stable material.

- Classification and Packaging: The final step in the manufacturing process is the classification of silica particles based on their size and shape. This allows for the production of different grades of silica with specific properties suited for various applications. The classified silica is then packaged and prepared for distribution.

It's important to note that the manufacturing process may vary depending on the specific application and requirements of silica. Different industries, such as glass manufacturing, semiconductor production, and construction, may employ additional steps or variations in the manufacturing process to meet their specific needs.

Understanding the manufacturing process of silica is crucial for ensuring the production of high-quality silica products with consistent properties. By following strict quality control measures and employing advanced manufacturing techniques, manufacturers can meet the increasing demand for silica across various industries.

Market Forecast and Growth Opportunities:

4.1. Current Market Trends:

The demand for silica continues to rise across multiple industries due to its indispensable properties. The construction, glass, and automotive sectors are driving the growth of the silica market, with increased infrastructure development and technological advancements.

4.2. Emerging Applications:

Silica is finding new applications in sectors such as electronics, renewable energy, and healthcare. Its use in advanced technologies like semiconductors, lithium-ion batteries, and pharmaceuticals is expected to propel the market further.

4.3. Regional Market Analysis:

The market for silica is witnessing significant growth in Asia Pacific, particularly in countries like China and India, due to rapid industrialization and urbanization. North America and Europe also contribute to the market demand, driven by infrastructure projects and technological innovations.

4.4. Future Outlook:

The future of the silica market appears promising, with a projected compound annual growth rate (CAGR) of X% during the forecast period. The increasing demand for sustainable materials, rising investments in infrastructure development, and technological advancements will fuel the growth of the silica market.

Conclusion:

The growing market for silica offers vast opportunities for businesses across multiple industries. Its diverse applications, coupled with the rising demand from construction, glass, and chemical sectors, make it a lucrative investment option. Manufacturers need to stay abreast of market trends, invest in research and development, and explore new applications to harness the full potential of silica in the ever-evolving industrial landscape.