The R-PET Chips and SSP Plant: (Recycled PET Chips) A Comprehensive Overview

The recycling and sustainable management of plastics have become critical concerns in today's environmentally conscious world. One of the most significant advancements in this area is the development of Recycled Polyethylene Terephthalate (R-PET) chips and the implementation of Solid State Polycondensation (SSP) plants. This article delves into the intricacies of R-PET chips, the functioning of SSP plants, and their crucial role in the global efforts towards sustainable plastic usage.

The global R-PET market reached around 4.85 million tonnes in 2022 and is expected to grow at a robust CAGR of 8.4% through 2032.

What Are R-PET Chips?

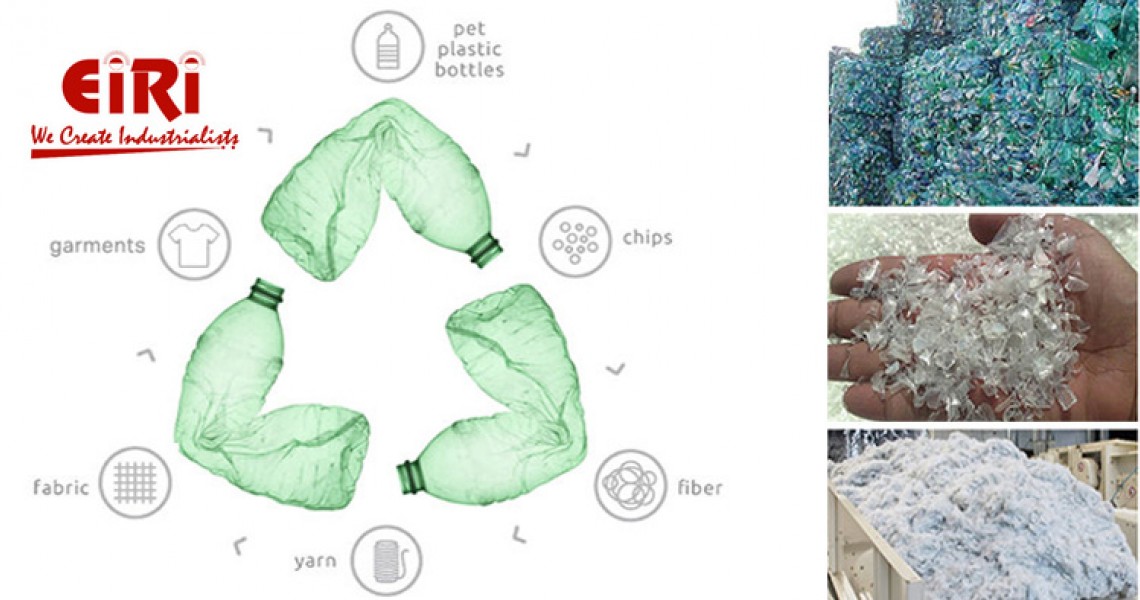

R-PET chips are recycled plastic pellets made from post-consumer PET (polyethylene terephthalate) bottles and other PET waste. PET is a type of plastic commonly used for packaging foods and beverages, especially soft drinks, juices, and water. The recycling process involves collecting, sorting, cleaning, and processing used PET products into small, uniform chips that can be reused to manufacture new PET products.

The Recycling Process

- Collection and Sorting: Used PET bottles are collected and sorted based on color and quality.

- Cleaning: The sorted PET is thoroughly cleaned to remove any contaminants, including labels, adhesives, and residues.

- Shredding: The cleaned PET is shredded into small flakes.

- Pelletizing: The flakes are melted and extruded to form R-PET chips.

Advantages of R-PET Chips

- Environmental Benefits: Recycling PET reduces the demand for virgin PET, thereby conserving natural resources and reducing the carbon footprint associated with plastic production.

- Energy Efficiency: Producing R-PET chips consumes less energy compared to manufacturing virgin PET.

- Economic Value: The recycling industry creates jobs and contributes to the economy by converting waste into valuable raw materials.

The Role of SSP Plants

Solid State Polycondensation (SSP) plants play a pivotal role in enhancing the quality of R-PET chips. SSP is a thermal process that increases the molecular weight of PET, improving its mechanical and thermal properties, which are often diminished during the initial recycling process.

How SSP Plants Work

- Pre-crystallization: R-PET chips are pre-crystallized to avoid agglomeration during the heating process.

- Heating: The pre-crystallized chips are heated in a controlled environment to a temperature just below the melting point of PET.

- Polycondensation: The chips undergo a polycondensation reaction in the solid state, which increases their molecular weight and intrinsic viscosity.

- Cooling and Final Processing: The SSP-treated chips are cooled and further processed for use in manufacturing new PET products.

Benefits of SSP in R-PET Production

- Improved Quality: SSP enhances the intrinsic viscosity of R-PET chips, making them suitable for applications requiring high mechanical strength and thermal stability.

- Consistency: The process ensures uniformity in the quality of R-PET chips, essential for reliable manufacturing processes.

- Versatility: SSP-treated R-PET chips can be used in a wide range of applications, including food-grade packaging, textiles, and industrial materials.

Applications of R-PET Chips and SSP-Treated R-PET

- Packaging: R-PET is commonly used in manufacturing new bottles and containers for food and beverages. The improved quality of SSP-treated R-PET makes it ideal for these applications, ensuring safety and durability.

- Textiles: R-PET fibers are used in the textile industry to produce clothing, upholstery, and carpeting. The use of recycled PET helps reduce the environmental impact of textile production.

- Construction Materials: Recycled PET is used to manufacture construction materials such as insulation, roofing tiles, and geotextiles, contributing to sustainable building practices.

- Automotive Industry: R-PET is used in the production of automotive parts, including seat covers, carpeting, and interior panels, promoting sustainability in the automotive sector.

- Consumer Goods: Various consumer goods, such as electronics casings, toys, and household items, are made using R-PET, demonstrating its versatility and wide applicability.

Challenges and Future Prospects

- Quality Control: Ensuring consistent quality in recycled PET can be challenging due to the variability in the feedstock.

- Contamination: Effective cleaning and decontamination of post-consumer PET are crucial to avoid impurities that can affect the final product quality.

- Market Acceptance: Convincing consumers and industries to adopt recycled PET products over virgin PET requires continuous education and awareness efforts.